2023 CFSEI DESIGN EXCELLENCE AWARD WINNERS

THIRD PLACE - RESIDENTIAL/HOSPITALITY

ADTEK ENGINEERS, INC. – ATLANTIC CROSSINGS BUILDING III

DELRAY BEACH, FLORIDA

Atlantic Crossings Building III Atlantic Crossings Building III

625 East Atlantic Avenue

Delray Beach, FL 33483

Completion Date: November 2022

Construction Cost: $22 million

Owner: Edwards Atlantic Avenue, LLC

Architect of Record: Paul Campbell, KEPHART

Engineer of Record for Structural Work: Robert Selinsky, Penoni & McCarthy & Associates

Cold-Formed Steel Specialty Engineer: Andrew Newland, ADTEK Engineers, Inc.

Cold-Formed Steel Specialty Contractor: Steve Watkins, Moraca Builders Inc. and Thomas Moraca III, Moraca Builders Inc.

Award Entry Submitted by: Andrew Newland, ADTEK Engineers, Inc.

Project Background

Atlantic Crossings Building III is part of a six-building redevelopment project which is being completed in two sequences, with Building III as part of the first sequence. The six buildings will have 261 high-quality apartments, 82 luxury condos, office space, and shops and restaurants. The redevelopment is described on the project website as "a green and walkable destination, it's a natural extension of Downtown Delray's authentic and eclectic charm, gracefully weaving together generous public spaces, lively streetscapes, and distinctive design to bring two city blocks to life."

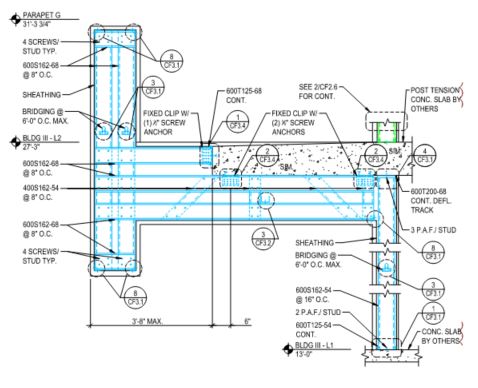

Building III specifically is one story of non-load bearing cold-formed steel (CFS) wall framing supported by the concrete foundation and post-tensioned concrete podium slab at the second level. Levels 2-5 are constructed with interior and exterior load-bearing CFS wall framing which supports timber floor trusses at Levels 3-5 and timber roof trusses, and X-braced CFS walls as the lateral system. Building III has retail units on Level 1 with residential units on upper floors.

Design Challenges and Solutions

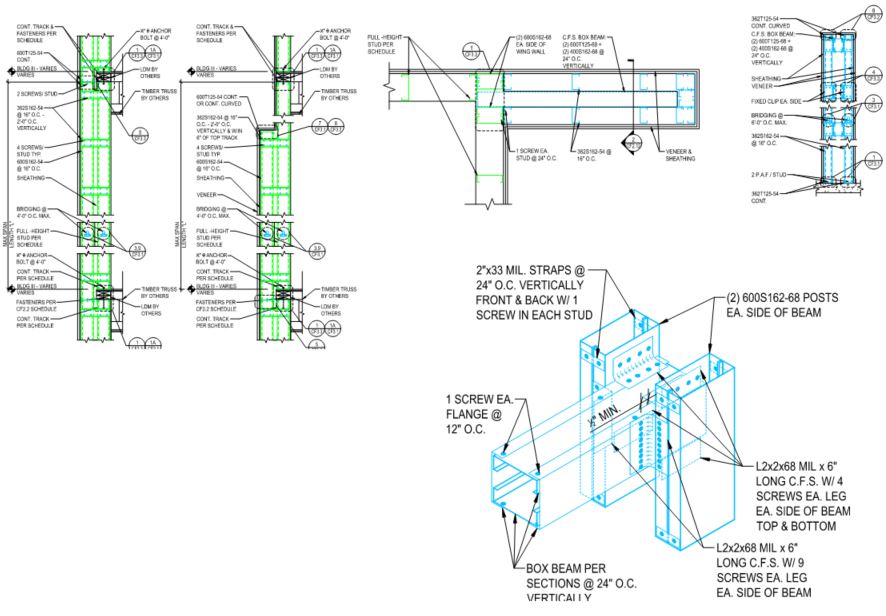

CFS framing was critical in meeting the aesthetic and structural challenges of this project. Challenges were presented during the design and construction phases. The first level boasts curved openings, wing walls, unique exterior soffit features, and difficult attachments to post-tensioned concrete. ADTEK worked with the specialty contractor to ensure adequate connections to post-tensioned concrete where soffit framing had significant cantilevers off of the post-tensioned slab. Segmented framing was used to create curved openings. At wingwalls, beams were designed to connect rigidly to typical wall framing to ensure adequate support.

Upper-level framing consisted of 6" exterior and 4" & 6" interior load bearing framing. Coordination with the timber truss manufacturer was critical during design and construction. Coordination was also critical for the green wall support. Design changes to the green wall were made after a substantial amount of the framing had been completed. Remediation was required to reinforce the load bearing framing with CFS posts for the additional lateral load imparted on the framing due to eccentric loading of the green wall. Studs were doubled up at the green wall support to accommodate additional loading and meet connection requirements.

The building also boasts a unique double wing-wall feature that is curved up the side of the building. This feature required some unique detailing to indicate the curve as it terminates up the building while connecting to the load bearing framing.

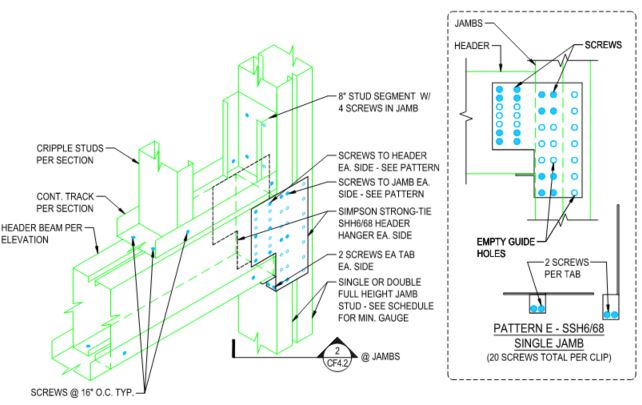

Openings also presented numerous challenges for this project. Several openings were offset from floor to floor. Applying jamb/jack loads to headers below created unfeasible header designs. To mitigate this, openings were designed to span the worst-case width, and non-load bearing framing was installed to build-out openings below longer header. This eliminated the need for HSS headers within the load bearing CFS wall framing. Another design issue involved the load bearing openings at some locations, where it was not feasible to install multiple jamb studs and a jack stud. Fortunately, Simpson Strong-Tie SHH (Steel Header Hanger) clips were able to be used to eliminate the need for jack studs in shorter openings. These clips were also t used throughout the project to eliminate the need for jack studs. Temporary openings were also requested in the load bearing framing. This request came during construction to accommodate the trash chute and lift. The trash chute was later infilled with non-load bearing wall framing and the lift was infilled with two non-load bearing openings.

As noted, the lateral resisting system utilized X-braced cold-formed steel walls in addition to masonry shear walls at stairs and elevators.

Atlantic Crossing Building III utilizes cold-formed steel in a number of different ways to achieve the desired aesthetic. From support of the green wall, unique soffit features, non-load bearing and load bearing framing, and various opening conditions, the versatility of cold-formed steel framing as well as proprietary CFS clips and their ability to work well with other construction methods ensured the success of this project

===============

==================

|