2022 CFSEI DESIGN EXCELLENCE AWARD WINNERS

THIRD PLACE – MUNICIPAL/SPORTS

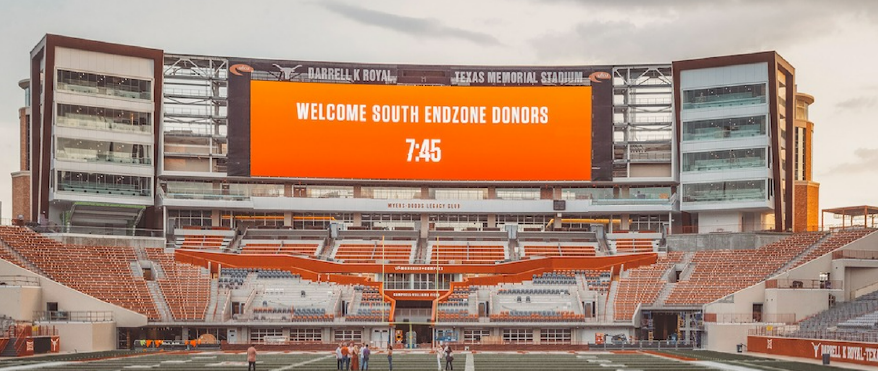

ADTEK ENGINEERS, INC. – DARRELL K ROYAL TEXAS MEMORIAL STADIUM

SOUTH END ZONE, AUSTIN, TEXAS

Darrell K Royal Texas Memorial Stadium South End Zone

2012 Robert Dedman Drive

Austin, Texas 78712

Completed: July 31, 2021

Construction Cost: $175 million

Owner: University of Texas

Architect of Record: Craig Kaufman, Populous

Engineer of Record for Structural Work: Brian Caudle, Walter P. Moore

Cold-Formed Steel Specialty Engineer: Mike Burkey, ADTEK Engineers, Inc.

Cold-Formed Steel Specialty Contractor: Laura Liem, Standard Drywall, Inc.

Award Entry Submitted by: Andrew Newland, P.E., ADTEK Engineers, Inc.

Project Background

Darrell K Royal Texas Memorial Stadium first opened on November 8, 1924. Since then, the stadium has undergone numerous expansions/renovations. The most recent renovation was the expansion of the south end zone and replacement of its bleacher seating. The expansion was meant to create a bowl-type stadium. Permanent seating, as well as new suites, loge boxes, and clubs were added. New offices and updates to the training facility were also included. The entrance tunnel is designed to look like the team logo for University of Texas at Austin Longhorns.

Design Challenges and Solutions

Cold-formed steel (CFS) as designed by ADTEK, was utilized in several areas. It was used as typical wall framing in both slab-to-slab conditions as well as bypass conditions. At some spandrel conditions, it was requested that CFS be used to brace the structural steel beams. CFS was used in numerous soffit conditions throughout the project, both inside and outside of the stadium. The versatility of CFS made it possible to achieve the curved and angled profiles that the architect desired. CFS was also used in large parapet/cornice framing at the towers. The CFS in these locations often bypassed the roof level and cantilevered out several feet from the structural steel support. In one such condition, sloped CFS framing bypassed multiple floors before bypassing the roof and cantilevering with a CFS "trussed" profile.

In addition to wall framing, CFS was also utilized in the seating areas at the club level. CFS is provided as infill between structural steel to support for barriers/tables between each level as well as divider walls.

CFS was also used for the interior meeting rooms. CFS framing supports raised concrete floors and stairs in these areas.

The expansion to the Darrell K Royal Texas Memorial Stadium provided a very modern update to a very high-profile college football program. Cold-formed steel was an integral part of completing and modernizing the stadium.

|