2018 CFSEI DESIGN EXCELLENCE AWARD WINNER

FIRST PLACE/RESIDENTIAL

CLARKDIETRICH ENGINEERING SERVICES – AIT BARRACKS COMPLEX PHASE 1, MONTEREY, CA

AIT Barracks Complex – Phase I AIT Barracks Complex – Phase I

1759 Lewis Road

Monterey, CA 93944

Completed: Fall 2017

Construction Cost: $56 million

Owner: U.S. Army Corps of Engineers

Architect of Record: SVA Architects, Inc.

Engineer of Record for Structural Work:

Patrick Earney, P.E., S.E., McClure Engineering Company

Cold-Formed Steel Specialty Engineer: Brent Owens, P.E., ClarkDietrich Engineering Services

Cold-Formed Steel Specialty Contractor: SWI Finishing, Inc.

Award Entry Submitted by: Brent Owens, P.E., ClarkDietrich Engineering Services

Project Background Project Background

The AIT Barracks facility in Monterey, CA is a $56 million, 110,000-square-foot structure used to house up to 320 Defense Language Institute students. The facility was commissioned by the U.S. Army Corps of Engineers to serve as a modernized, private-sector residence and replace outdated facilities at Presidio of Monterey. In addition to modern amenities, the structure also boasts many sustainability features such as solar panels, rainwater collectors and highly efficient HVAC systems.

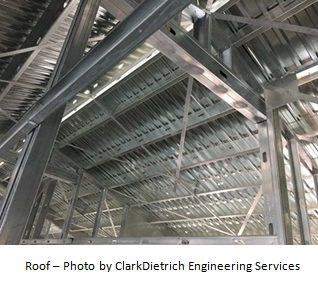

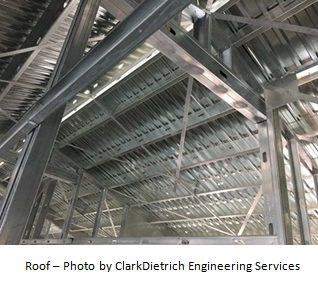

The structure itself consists of cold-formed steel trusses and rafters at the roof supporting synthetic stone tiles. The floor system was constructed of cold-formed steel joists topped with metal decking and gypsum concrete. Four stories of load-bearing cold-formed steel wall studs support the roof and floor framing, in addition to a four-story fully grouted and reinforced masonry wall adjacent to the access road. The masonry wall was required to meet United Facilities Criteria (UFC) antiterrorism requirements where cold-formed steel wall studs could not resist the prescribed design loads. Elevator and stair shafts were also constructed using cold-formed steel framing.

Design Challenges Design Challenges

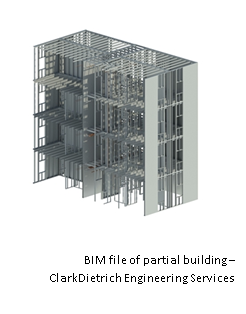

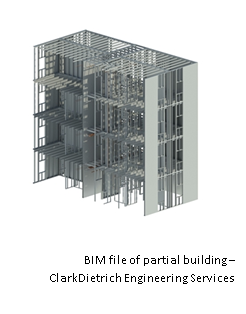

What makes this structure unique are the numerous lateral and vertical design considerations in addition to a massive coordination effort between trades through BIM (Building Information Modeling) and panelization. ClarkDietrich served as both the Specialty Cold-Formed Engineer as well as the project Engineer of Record. McClure Engineering was responsible for the foundation and slab design as well as the masonry wall framing. Numerous other designers were involved with the coordination of HVAC, electrical and plumbing systems throughout the building.

ClarkDietrich was also contracted to provide a full BIM model for both structural and nonstructural framing at a

detail level of 350, in addition to panel drawings for the structural walls. Joist framing was coordinated and prefabricated on site by the installer.

The structure is located in a high seismic region, which required a large number of shear walls and hold-downs. To resist seismic loading, sheet steel was used to provide overall stability to a majority of the structure with the exception of the masonry wall along the access road. Proprietary shear wall posts were connected with prefabricated hold-downs between floors. At the foundation, tension loads on the shear wall posts exceeded the capacity of post-installed concrete anchors, requiring structural steel plates which were precast into the foundation. These structural steel plates were designed by McClure Engineering to resist the seismic tension forces at the shear wall posts. Small structural plates were welded to each shear wall post and then down to the embed plates, allowing for field adjustment. ClarkDietrich also provided layout drawings which depicted the exact location of nearly 300 shear wall post embed plates to within 1/8-inch utilizing the BIM model. During installation of the first-floor panels, it was discovered that only one of the precast embed plates was installed out of tolerance, resulting in a proper alignment rate of over 99.5 percent. The structure is located in a high seismic region, which required a large number of shear walls and hold-downs. To resist seismic loading, sheet steel was used to provide overall stability to a majority of the structure with the exception of the masonry wall along the access road. Proprietary shear wall posts were connected with prefabricated hold-downs between floors. At the foundation, tension loads on the shear wall posts exceeded the capacity of post-installed concrete anchors, requiring structural steel plates which were precast into the foundation. These structural steel plates were designed by McClure Engineering to resist the seismic tension forces at the shear wall posts. Small structural plates were welded to each shear wall post and then down to the embed plates, allowing for field adjustment. ClarkDietrich also provided layout drawings which depicted the exact location of nearly 300 shear wall post embed plates to within 1/8-inch utilizing the BIM model. During installation of the first-floor panels, it was discovered that only one of the precast embed plates was installed out of tolerance, resulting in a proper alignment rate of over 99.5 percent.

The structure was also required to resist UFC 4-010-01 requirements for blast loading applied to the exterior framing, in addition to UFC 4-023-03 progressive collapse requirements. A creative solution to meeting the progressive collapse requirement for the exterior walls required running the joist framing from demising wall to demising wall. The end joists at the exterior wall were then designed to support the wall and roof loading above. This allowed for large sections of exterior wall framing to be removed, while still providing vertical support to the structure above, which satisfied the progressive collapse requirements. At three end locations where the floor and roof were supported by stud framing, structural steel tubes were designed in line with the joist framing, allowing for progressive collapse requirements to be met if the bearing wall below were removed. The structure was also required to resist UFC 4-010-01 requirements for blast loading applied to the exterior framing, in addition to UFC 4-023-03 progressive collapse requirements. A creative solution to meeting the progressive collapse requirement for the exterior walls required running the joist framing from demising wall to demising wall. The end joists at the exterior wall were then designed to support the wall and roof loading above. This allowed for large sections of exterior wall framing to be removed, while still providing vertical support to the structure above, which satisfied the progressive collapse requirements. At three end locations where the floor and roof were supported by stud framing, structural steel tubes were designed in line with the joist framing, allowing for progressive collapse requirements to be met if the bearing wall below were removed.

In addition to panelization of the wall and joist framing, another creative solution used to speed the pace of construction was a ledger construction technique. Bearing wall studs were stacked directly on top of each other with joists and rafters framing into the sides of the wall. This allowed for metal decking to be installed at each floor level without the need for the gypcrete floors to be fully installed. In addition, deep leg tracks were used at the base of the second-, third- and fourth-floor walls in order to double as the base track and a pour stop for the gypcrete topping. Construction delays were avoided because the wall and joist installation were not dependent upon completion of the floor finishes. In addition to panelization of the wall and joist framing, another creative solution used to speed the pace of construction was a ledger construction technique. Bearing wall studs were stacked directly on top of each other with joists and rafters framing into the sides of the wall. This allowed for metal decking to be installed at each floor level without the need for the gypcrete floors to be fully installed. In addition, deep leg tracks were used at the base of the second-, third- and fourth-floor walls in order to double as the base track and a pour stop for the gypcrete topping. Construction delays were avoided because the wall and joist installation were not dependent upon completion of the floor finishes.

The AIT Barracks project is a four-story, load-bearing, cold-formed steel structure that required several “out of the box” solutions to keep the project on time and on budget. From high seismic loading, antiterrorism requirements and a mix of cold-formed steel, masonry and structural steel, this project encompassed several very difficult design challenges.

Download project details in PDF

|

AIT Barracks Complex – Phase I

AIT Barracks Complex – Phase I Project Background

Project Background  Design Challenges

Design Challenges The structure is located in a high seismic region, which required a large number of shear walls and hold-downs. To resist seismic loading, sheet steel was used to provide overall stability to a majority of the structure with the exception of the masonry wall along the access road. Proprietary shear wall posts were connected with prefabricated hold-downs between floors. At the foundation, tension loads on the shear wall posts exceeded the capacity of post-installed concrete anchors, requiring structural steel plates which were precast into the foundation. These structural steel plates were designed by McClure Engineering to resist the seismic tension forces at the shear wall posts. Small structural plates were welded to each shear wall post and then down to the embed plates, allowing for field adjustment. ClarkDietrich also provided layout drawings which depicted the exact location of nearly 300 shear wall post embed plates to within 1/8-inch utilizing the BIM model. During installation of the first-floor panels, it was discovered that only one of the precast embed plates was installed out of tolerance, resulting in a proper alignment rate of over 99.5 percent.

The structure is located in a high seismic region, which required a large number of shear walls and hold-downs. To resist seismic loading, sheet steel was used to provide overall stability to a majority of the structure with the exception of the masonry wall along the access road. Proprietary shear wall posts were connected with prefabricated hold-downs between floors. At the foundation, tension loads on the shear wall posts exceeded the capacity of post-installed concrete anchors, requiring structural steel plates which were precast into the foundation. These structural steel plates were designed by McClure Engineering to resist the seismic tension forces at the shear wall posts. Small structural plates were welded to each shear wall post and then down to the embed plates, allowing for field adjustment. ClarkDietrich also provided layout drawings which depicted the exact location of nearly 300 shear wall post embed plates to within 1/8-inch utilizing the BIM model. During installation of the first-floor panels, it was discovered that only one of the precast embed plates was installed out of tolerance, resulting in a proper alignment rate of over 99.5 percent. The structure was also required to resist UFC 4-010-01 requirements for blast loading applied to the exterior framing, in addition to UFC 4-023-03 progressive collapse requirements. A creative solution to meeting the progressive collapse requirement for the exterior walls required running the joist framing from demising wall to demising wall. The end joists at the exterior wall were then designed to support the wall and roof loading above. This allowed for large sections of exterior wall framing to be removed, while still providing vertical support to the structure above, which satisfied the progressive collapse requirements. At three end locations where the floor and roof were supported by stud framing, structural steel tubes were designed in line with the joist framing, allowing for progressive collapse requirements to be met if the bearing wall below were removed.

The structure was also required to resist UFC 4-010-01 requirements for blast loading applied to the exterior framing, in addition to UFC 4-023-03 progressive collapse requirements. A creative solution to meeting the progressive collapse requirement for the exterior walls required running the joist framing from demising wall to demising wall. The end joists at the exterior wall were then designed to support the wall and roof loading above. This allowed for large sections of exterior wall framing to be removed, while still providing vertical support to the structure above, which satisfied the progressive collapse requirements. At three end locations where the floor and roof were supported by stud framing, structural steel tubes were designed in line with the joist framing, allowing for progressive collapse requirements to be met if the bearing wall below were removed. In addition to panelization of the wall and joist framing, another creative solution used to speed the pace of construction was a ledger construction technique. Bearing wall studs were stacked directly on top of each other with joists and rafters framing into the sides of the wall. This allowed for metal decking to be installed at each floor level without the need for the gypcrete floors to be fully installed. In addition, deep leg tracks were used at the base of the second-, third- and fourth-floor walls in order to double as the base track and a pour stop for the gypcrete topping. Construction delays were avoided because the wall and joist installation were not dependent upon completion of the floor finishes.

In addition to panelization of the wall and joist framing, another creative solution used to speed the pace of construction was a ledger construction technique. Bearing wall studs were stacked directly on top of each other with joists and rafters framing into the sides of the wall. This allowed for metal decking to be installed at each floor level without the need for the gypcrete floors to be fully installed. In addition, deep leg tracks were used at the base of the second-, third- and fourth-floor walls in order to double as the base track and a pour stop for the gypcrete topping. Construction delays were avoided because the wall and joist installation were not dependent upon completion of the floor finishes.