2025 CFSEI CREATIVE DETAIL AWARD WINNER

SECOND PLACE

SALAS O’BRIEN - CONFIDENTIAL CASINO HOTEL TOWER

EASTERN UNITED STATES

Confidential Casino Hotel Tower Confidential Casino Hotel Tower

Eastern United States

Completion Date: December 2024

Construction Cost: $800 Million

Owner: Confidential Owner.

Architect of Record: Manell Companies.

Engineer of Record for Structural Work: Kris Barker, Barker Structural.

Cold-Formed Steel Panelized Framing Specialty Engineer: Daniel Stadig, P.E., Salas O’Brien.

Cold-Formed Steel Specialty Contractor: Jared Schumaker, Advanced Exterior Systems.

Award Entry Submitted by: Daniel Stadig, P.E., Salas O’Brien.

Project Background

Salas O’Brien faced the challenge of designing cold-formed steel (CFS) framing for a new, 320-key casino hotel tower with extensive prefabricated and pre-fined EIFS CFS wall panels and curtain wall glazing.

Design Challenges and Solutions

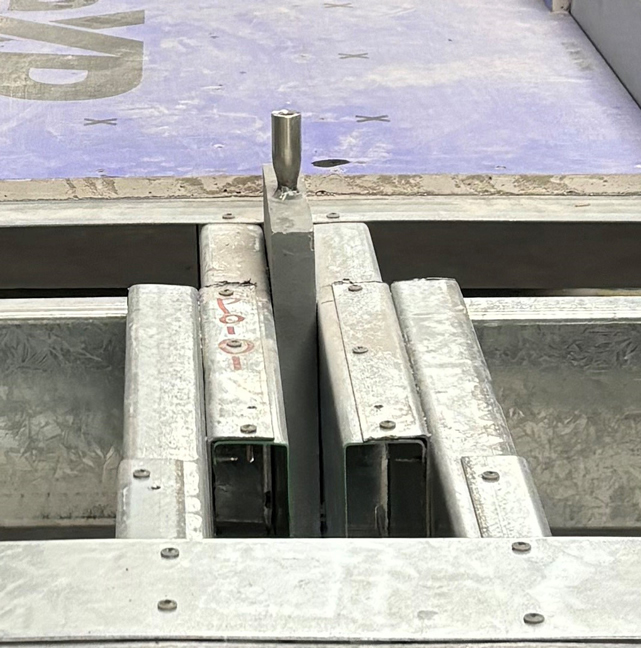

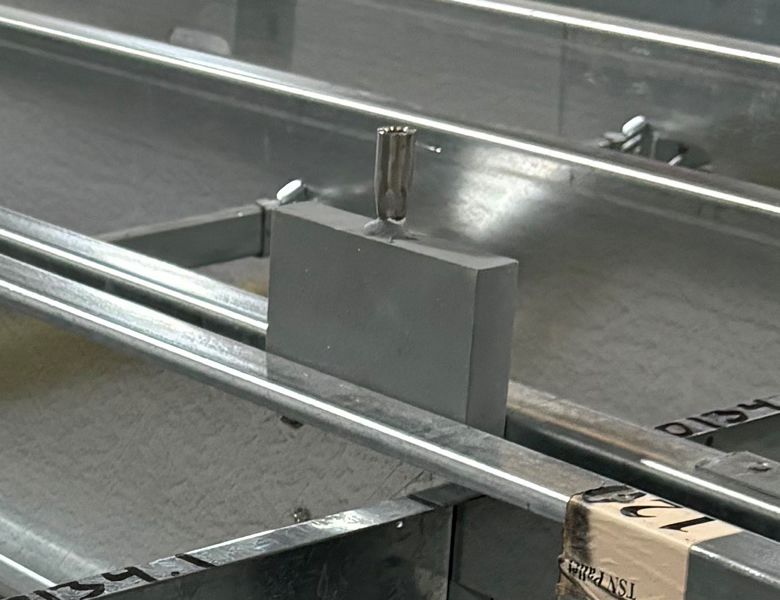

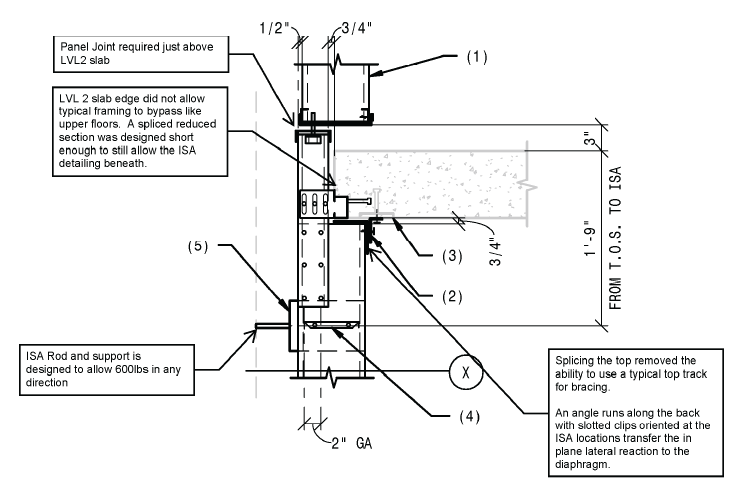

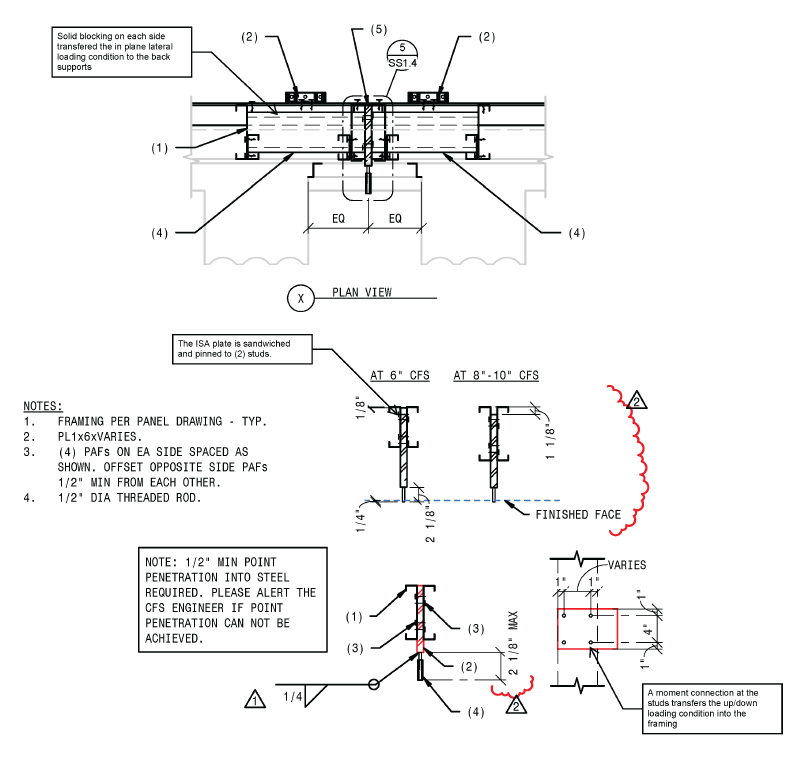

A prominent design challenge was providing support for the window washing system tie-back points called intermittent stabilization anchors (ISAs). The pre-finished panels were needed to provide the support point without extensive field installation requirements.

The original design from the SER assumed HSS posts were needed behind, or embedded in, the wall framing to provide this support. Salas O’Brien created a design that could eliminate the HSS posts and allow a pre-installed support method within the panels using standard CFS material and connectors.

Removing HSS posts and providing a CFS solution not only provided the necessary support point but also minimized fieldwork, incorporating substantial savings into the project.

The provided solution uses a sandwiched knife plate pinned to stud webs. The adjacent stud bays are solid-blocked to allow transfer to the back side of the framing and connection into the diaphragms.

The details below show the complexity required for just one of the four conditions for a finished prefabricated construction method that could fit the required panel tiebacks and supports near the diaphragms. This condition shows the ISA height just under the Level 2 slab, where a spliced reduced section was already required to allow bypass.

The detail exemplifies the versatility of available framing and clips for CFS engineers to design unique and efficient solutions for the project.

Salas O’Brien’s design provided an opportunity for significant savings relative to the previous solution using HSS posts, and it allowed the planned prefabrication and erection schedule assumptions to remain the basis for choosing a prefabrication system.

|