2021 CFSEI DESIGN EXCELLENCE AWARD WINNERS

THIRD PLACE – COMMERCIAL

THE LEFFLER GROUP – UCHEALTH STEADMAN HAWKINS CLINIC

ENGLEWOOD, COLORADO

UCHealth Steadman Hawkins Clinic

175 Inverness Drive West

Englewood, Colorado

Completed: June 2019

Owner: UCHealth

Architect of Record: BSA Lifestructures

Engineer of Record for Structural Work: Stewart, Inc.

Cold-Formed Steel Specialty Engineer: The Leffler Group.

Cold-Formed Steel Specialty Contractor: Spacecon Specialty Contractors

Award Entry Submitted by: Daniel Stadig, P.E., The Leffler Group

Project Background

The UCHealth Steadman Hawkins Clinic is a 13,000-square-foot, four-story multipurpose medical and rehabilitation center. It contains multiple sports-related medical clinics, a surgical center, walk-in orthopedic services, as well as physical therapy utilities such as an outdoor field and indoor gym.

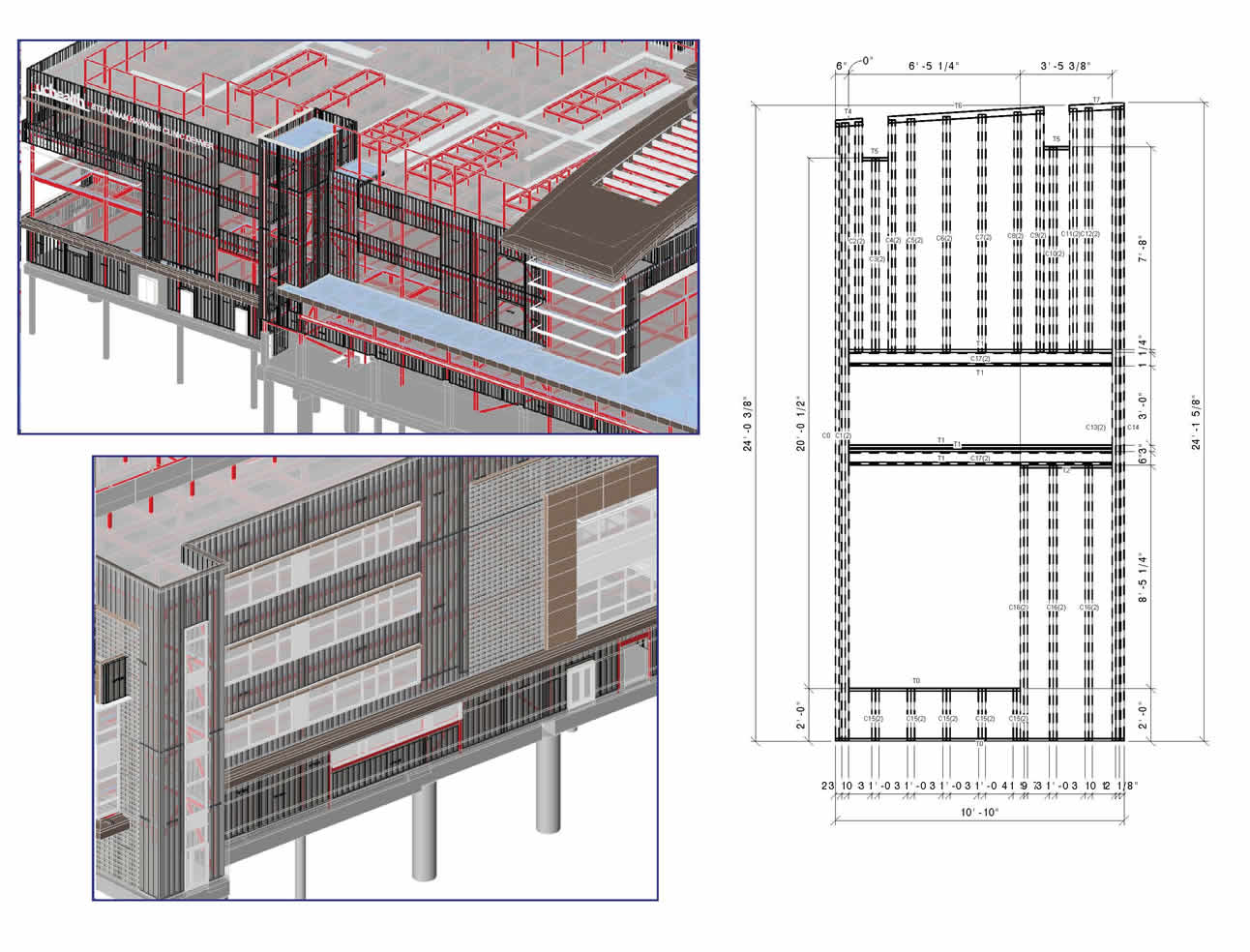

The UCHealth Steadman Hawkins Clinic construction type consists of a steel frame, composite concrete deck diaphragm, steel-braced frames and cold-formed steel exterior envelope.

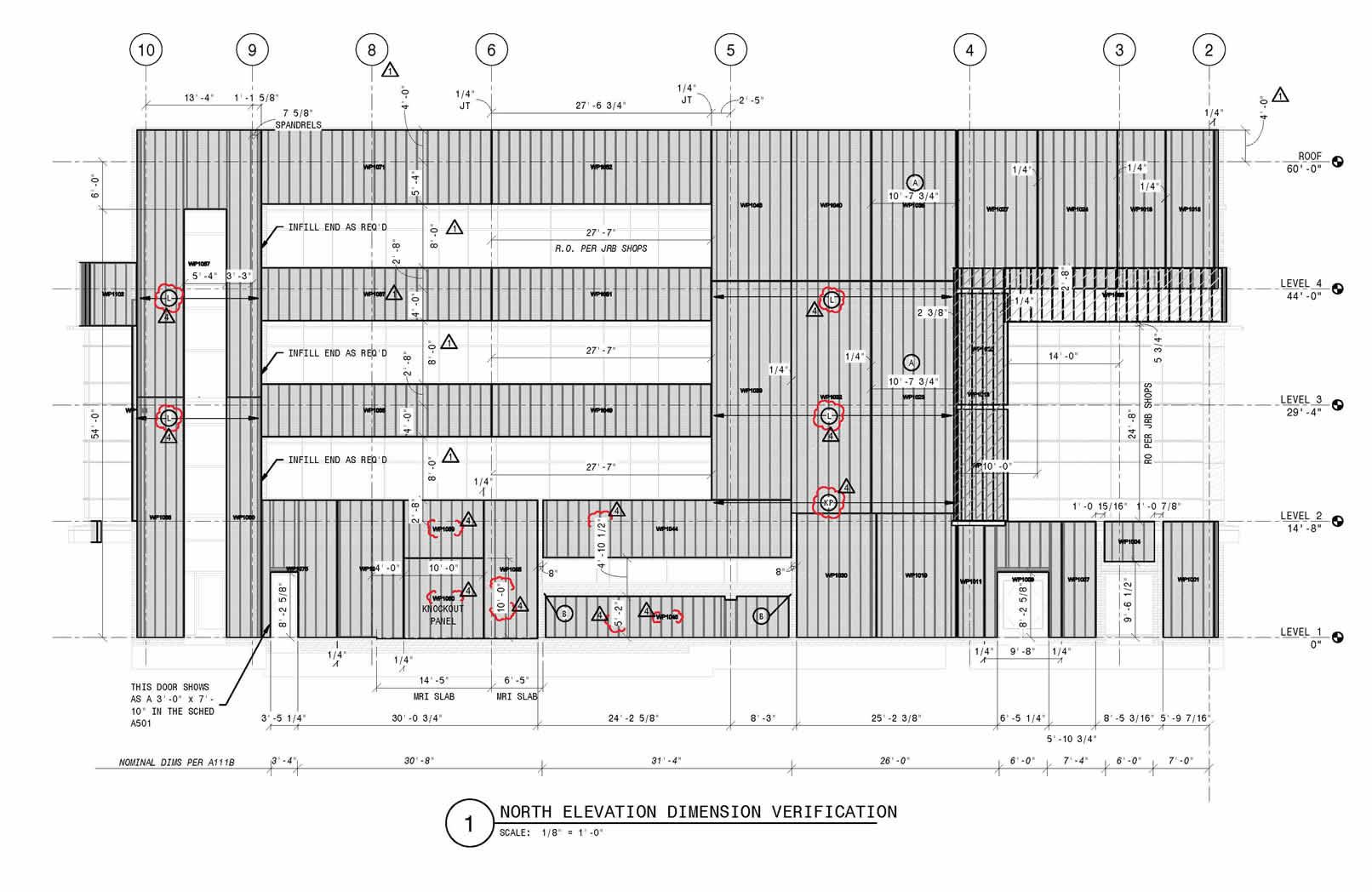

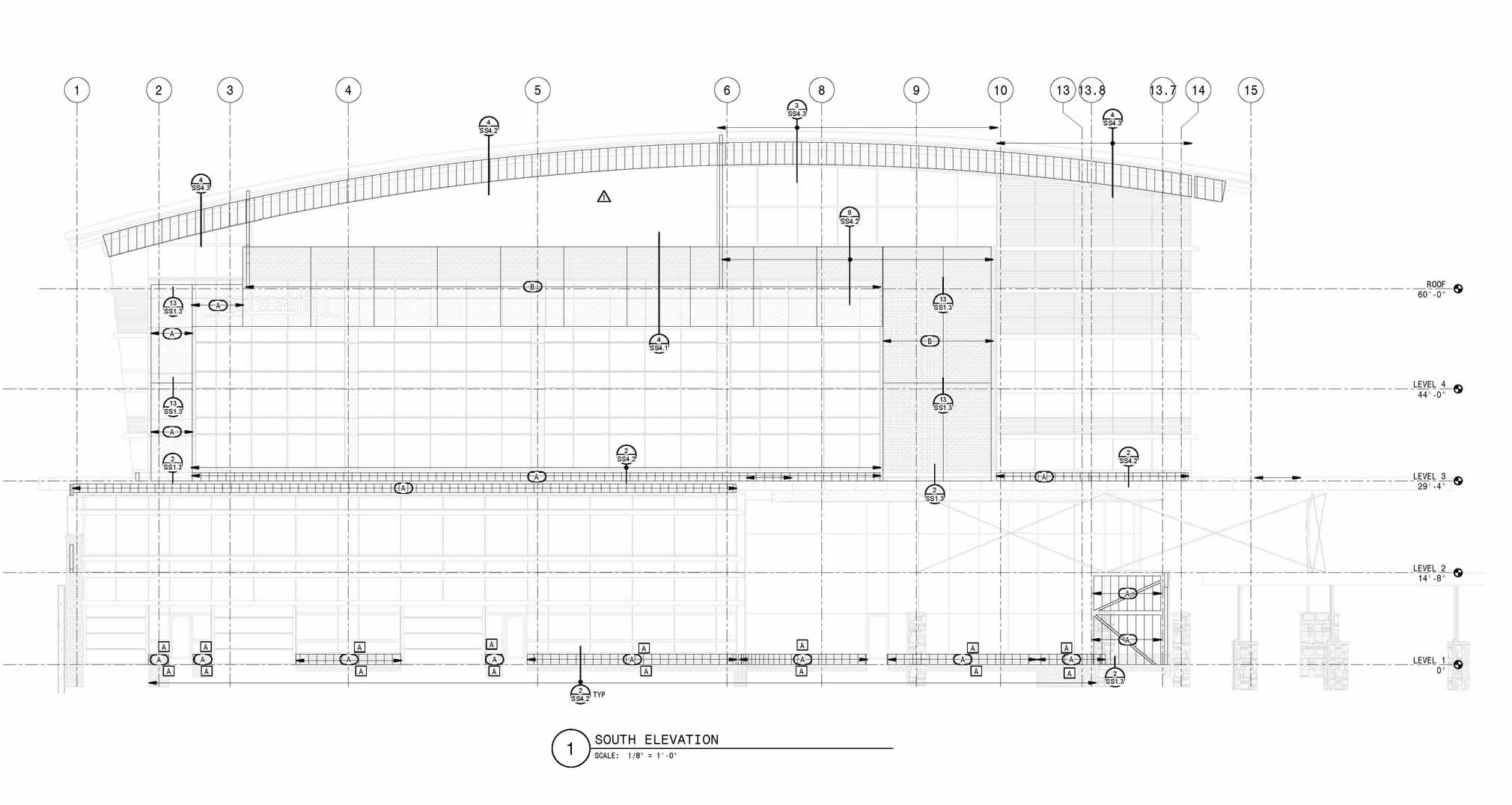

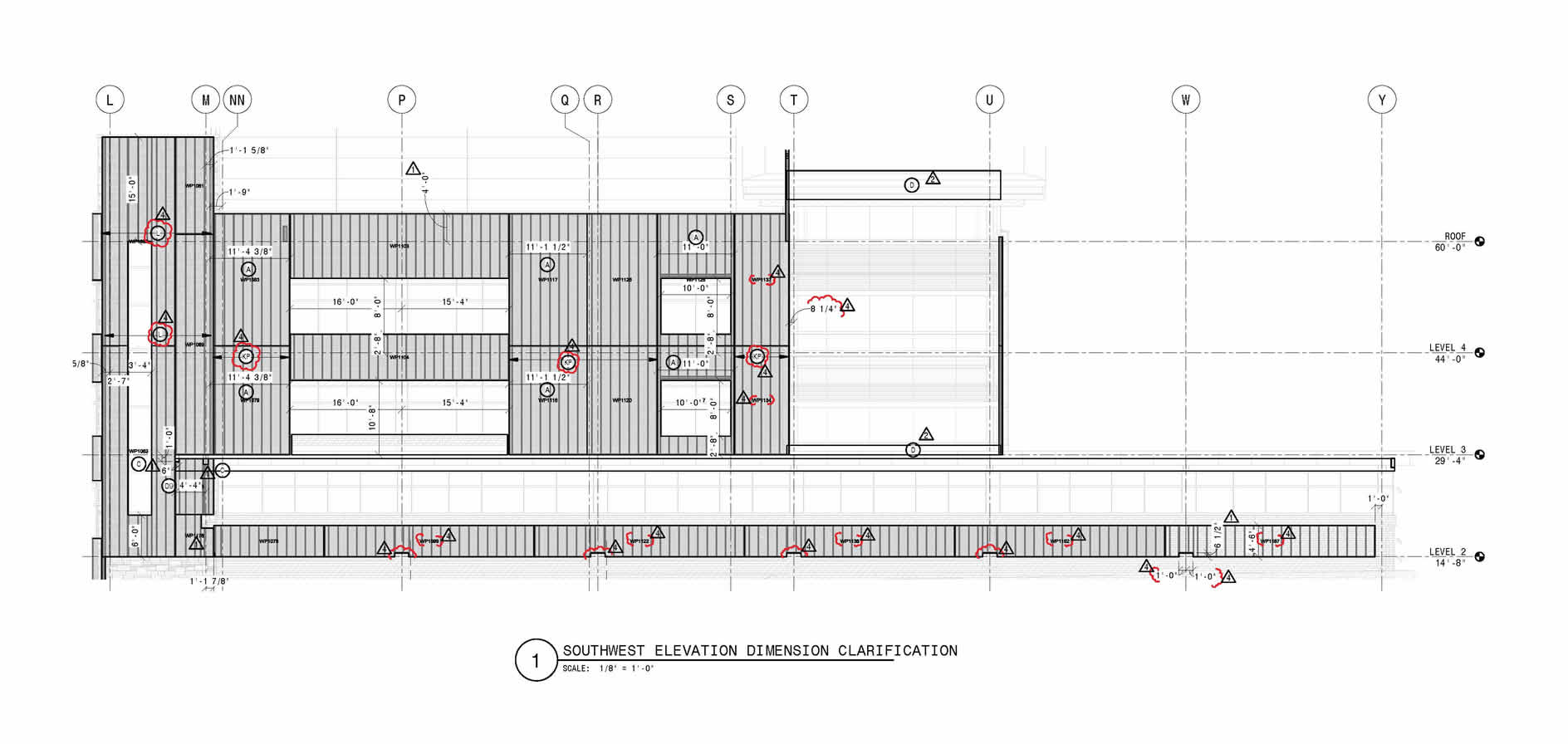

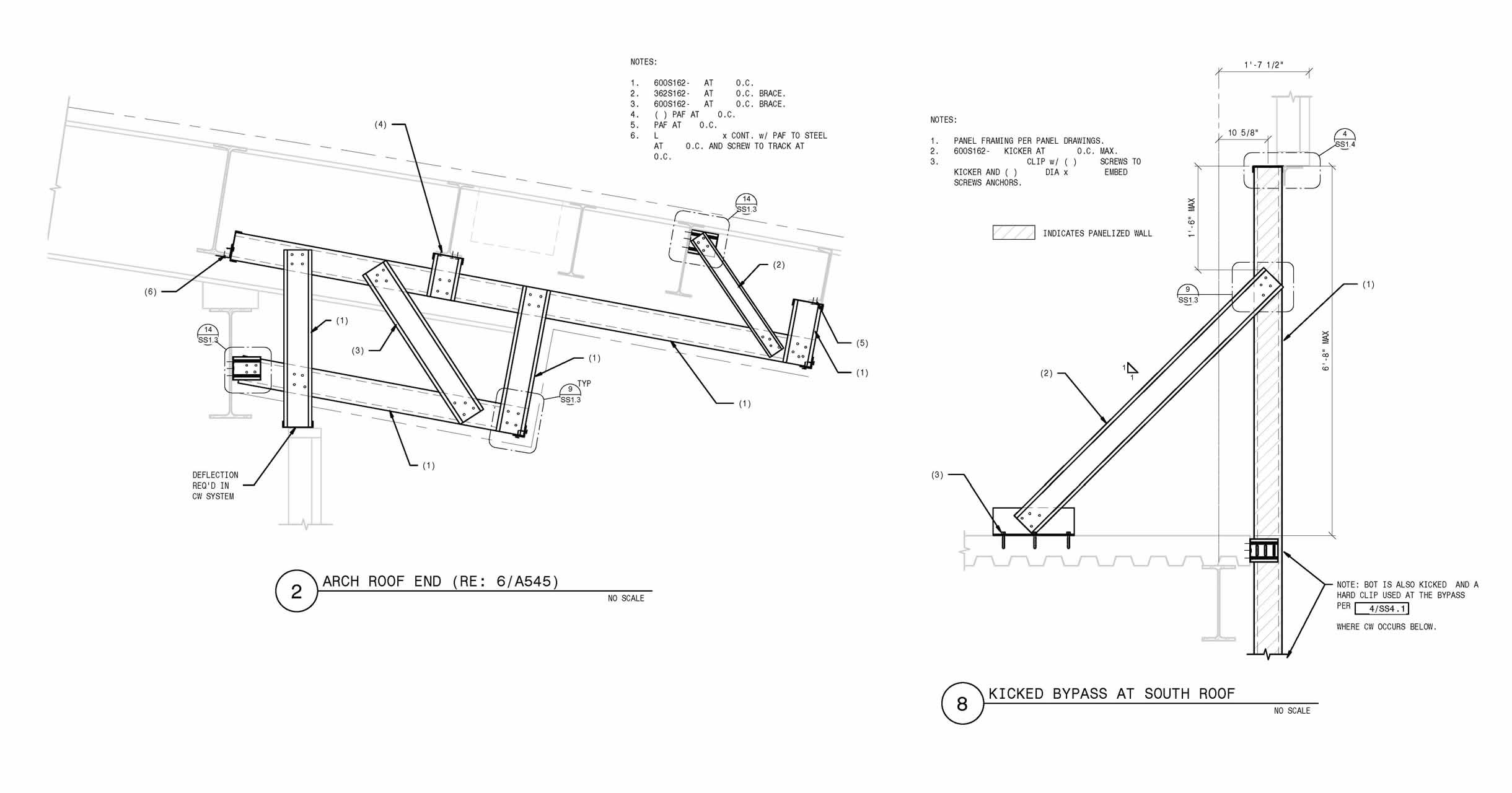

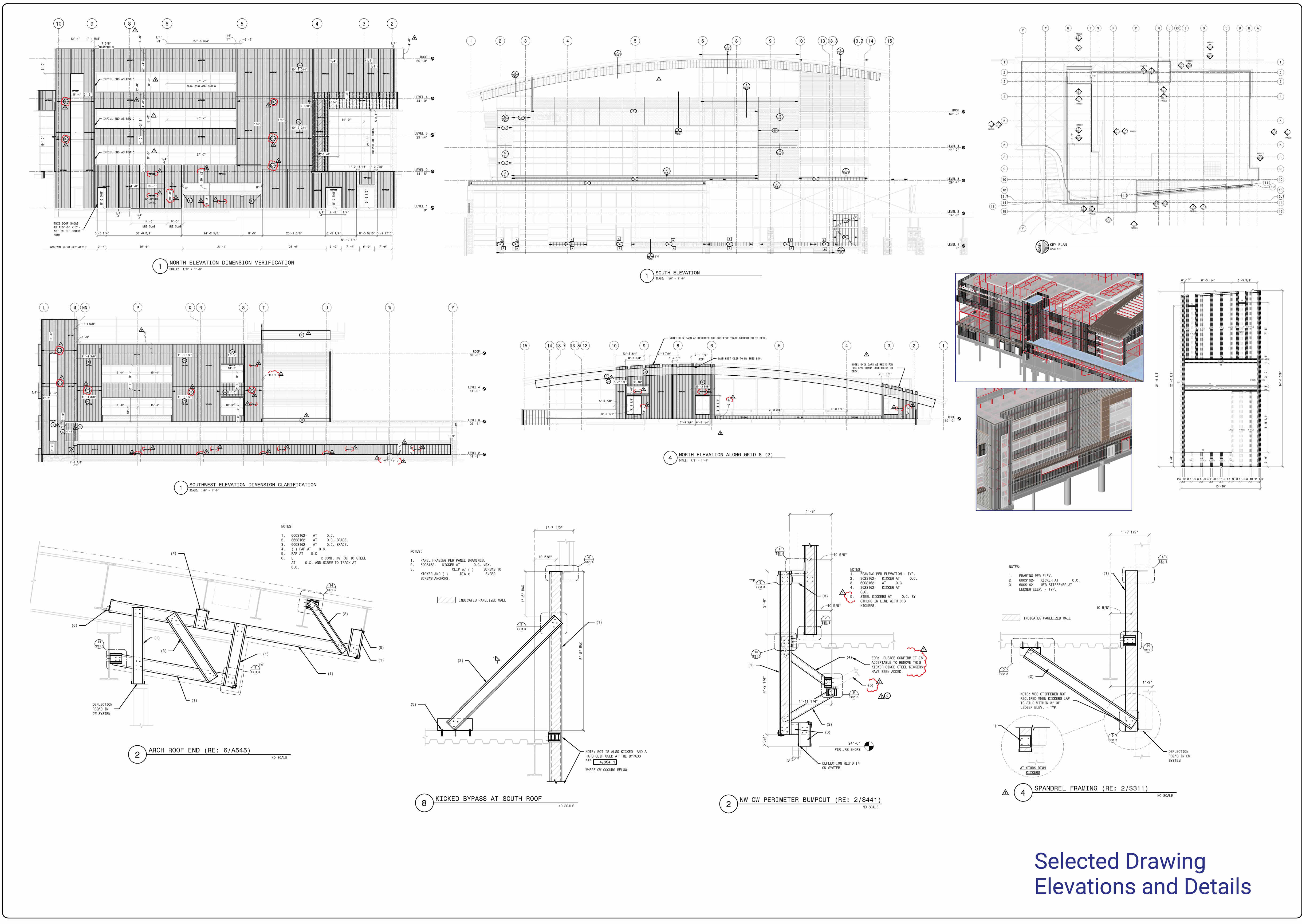

The building’s exterior consists of large glass facades, 196 cold-formed steel panels, and miscellaneous cold-formed steel field framing where panelization was not utilized, such as the barrel roof fascia framing.

The Leffler Group was challenged with creating a panelized solution for the exterior envelope construction.

Design Challenges and Solutions

There were significant design challenges presented by this project, including:

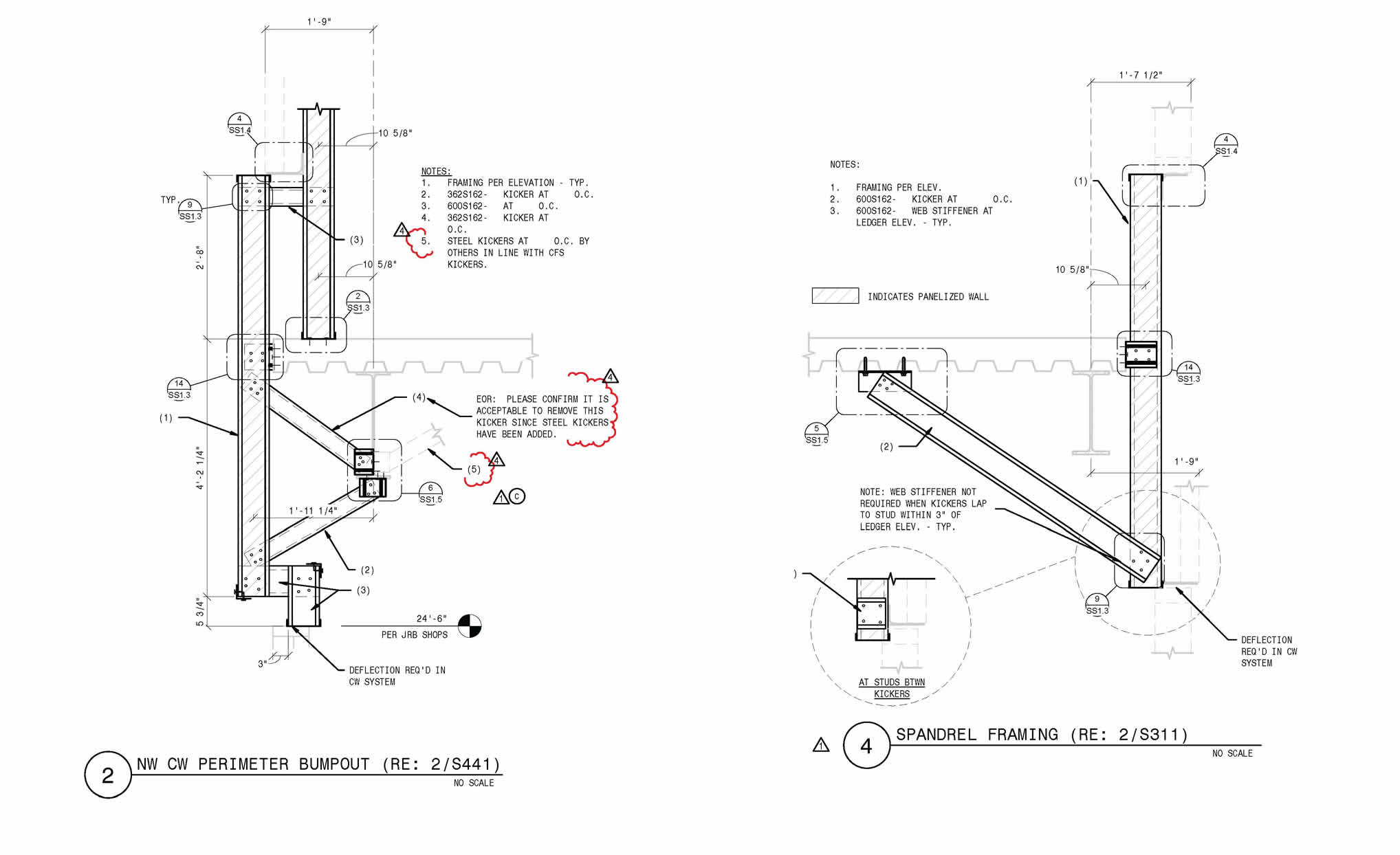

Contract document coordination did not consider panelization during design: The UCHealth Steadman Hawkins Clinic facility envelope design presented important challenges to panelization largely due to the design team not expecting panelization while coordinating the envelope detailing and schematic design. The facility envelope design contained multiple cladding systems, varying and inconsistent envelope detailing, and curved roof facades that lend minimal economy of repetition typically utilized in panelization.

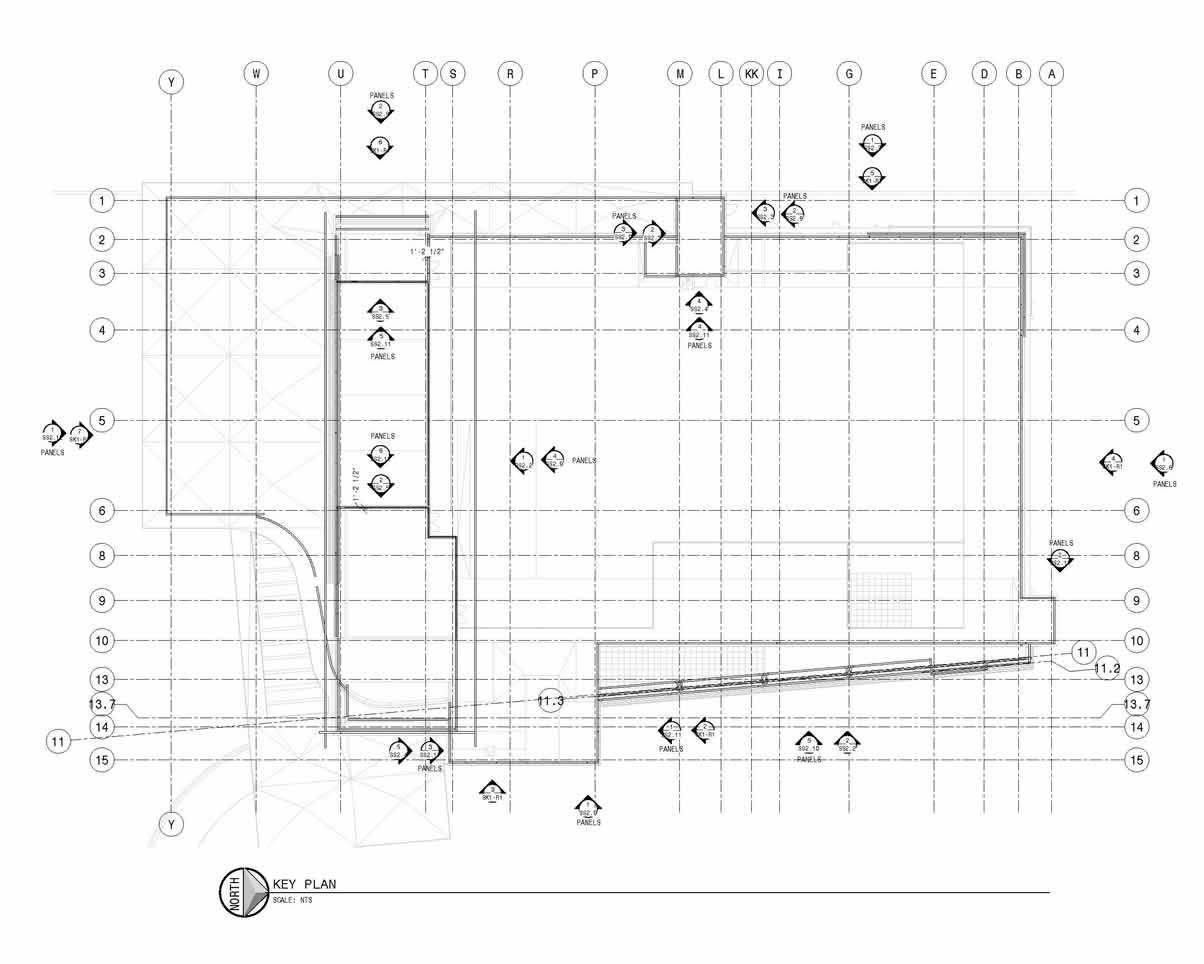

No repetition or simplification in panels: Few panels of about 200 were considered identical. Each panel required careful coordination with the expected integration and relation to the superstructure, adjacent panel, and adjacent curtain wall framing. Erection detailing required panel attachment and tiebacks to the structure that resembled field framed systems due to the available coordination and framing relation to the primary structure. Brick ledgers above Level 2 varied by location and floor, and several panels required design for support of post-erection installed welded ledgers.

Successful cold-formed steel panelization of this envelope exemplifies how experienced planning and detailing of cold-formed steel systems can still be achieved for modern complicated architectural designs. The level of detail in coordination for the panelization may not have been achieved without full Building Information Modeling (BIM) utilization.

|