2021 CFSEI DESIGN EXCELLENCE AWARD WINNERS

SECOND PLACE – MUNICIPAL

ADTEK ENGINEERS, INC. – LGA CENTRAL TERMINAL B REPLACEMENT

QUEENS, NEW YORK

LaGuardia Airport (LGA) Central Terminal B Replacement LaGuardia Airport (LGA) Central Terminal B Replacement

Queens, New York 19118

Completed: June 2020

Construction Cost: $1.1 Billion

Owner: LaGuardia Gateway Partners

Architect of Record: James Christerson, Parsons Brinkerhoff/HOK JV

Engineer of Record for Structural Work: Thornton Tomasetti

Cold-Formed Steel Specialty Engineer: Andrew Newland, P.E., ADTEK Engineers, Inc.

Cold-Formed Steel Specialty Contractor: Robert Doxey, Cord Contracting Co. Inc.

Award Entry Submitted by: Andrew Newland, P.E., ADTEK Engineers, Inc.

Project Background

LaGuardia Airport (LGA), located in Queens, New York, first opened commercially in 1939. As of 2018, 30 million passengers had traveled through LGA, with Terminal B handling most of the airport's traffic. LaGuardia Airport (LGA), located in Queens, New York, first opened commercially in 1939. As of 2018, 30 million passengers had traveled through LGA, with Terminal B handling most of the airport's traffic.

Since opening, LGA has had several renovations. The current renovations include the rebuilding and connection of all four terminals (2.7 million square feet with six new concourses & 79 gates), two miles of aircraft taxiways, a 3,000-space parking garage and a proposed AirTrain.

This specific phase of the overall construction included four levels of structural steel superstructure with concrete on metal deck. The exterior utilized cold-formed steel (CFS) framing and metal wall panels.

The interior featured numerous commissioned art projects, including a multi-story tiled mural showcasing New York City.

Design Challenges and Solutions

ADTEK provided cold-formed steel design services for several areas within the LGA Headhouse. Design of the exterior cold-formed steel framing had several complexities. The project utilized a wind study which showed extremely high maximum wind pressures equaling 106 PSF, 136 PSF and 50 PSF for facade, roof, and soffit framing, respectively. These high wind loads were coupled with very large spans. Some spans were up to 25 feet long and varied as slab-to-slab and bypass. Slab-to-slab connections required large gauges and deep members to meet deflection requirements. Bypass conditions still required heavy gauges and deep members, but also made connections to the slab edge difficult. In addition to high wind loads, blast design was required in portions of the building. ADTEK worked with the engineer of record’s blast team to create special connection details and connections. These blast loads required clips to be specially manufactured with larger slots to accommodate additional fasteners at slip locations.

In addition to exterior framing, ADTEK provided designs for several different interior areas. The LGA Headhouse has glass fiber reinforced concrete (GFRC) ceilings and columns throughout, which required structural CFS framing as backup. This framing required extensive coordination with the contractor to frame areas around MEP equipment. ADTEK provided engineering for check-in counter ceilings, which incorporated stud and strut framing to support the ceilings while avoiding MEP equipment. ADTEK also provided design at retail ceilings using proprietary stud joist framing to accomplish large spans as well as provide areas for MEP to span through. MEP was also required to be supported on top of the joist framing.

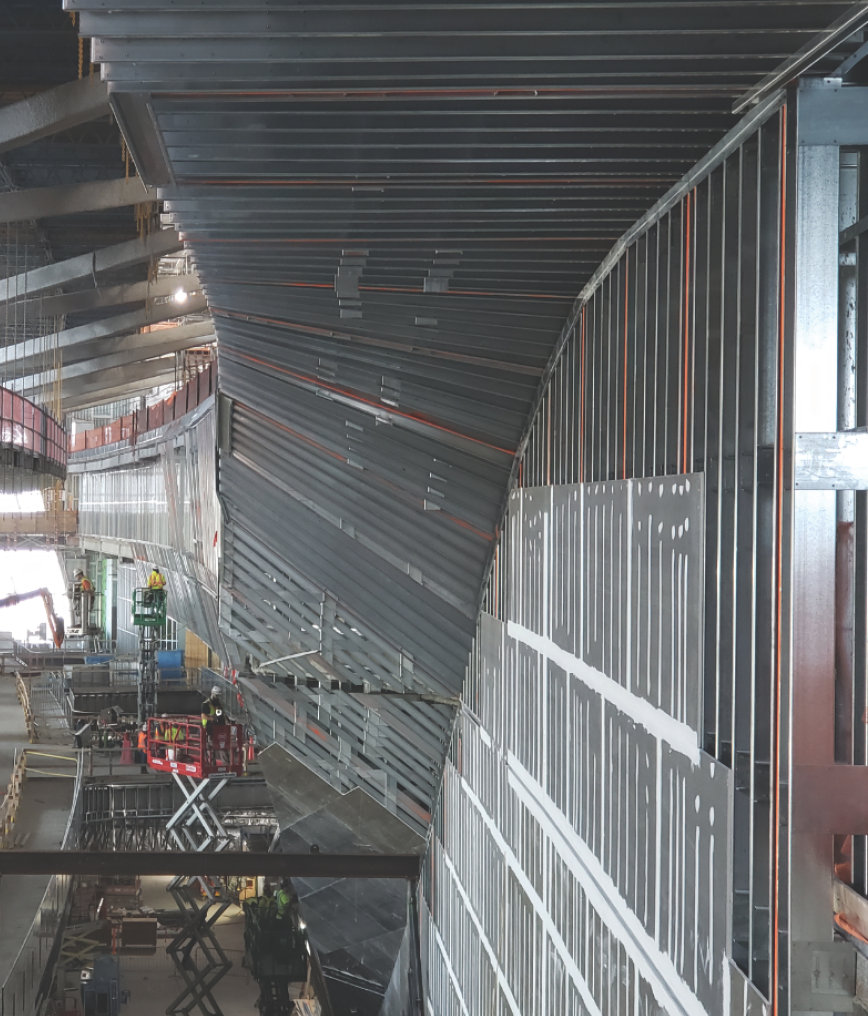

One of the largest sections of the interior requiring cold-formed steel framing was the Feature Wall, which spans from Level 2 to above Level 4. The feature is a magnificent, tiled mural that highlights New York City.

The feature wall framing has movement joints at various heights above or below the slab level and is supported at various distances from the slab. This was achieved using standard CFS framing in a truss-like pattern to create the illusion of movement in the wall. Numerous other areas were designed to accommodate large spans or support hanging veneers. CFS framing was critical for the construction of the interior and exterior of the LGA Headhouse.

|