2021 CFSEI DESIGN EXCELLENCE AWARD WINNERSSECOND PLACE – COMMERCIALCLARKDIETRICH ENGINEERING SERVICES LLC – ARHAUS FURNITURE - OAK BROOK, ILLINOIS

Arhaus Furniture Completed: February 2021 Owner: Brookfield Properties Project Background

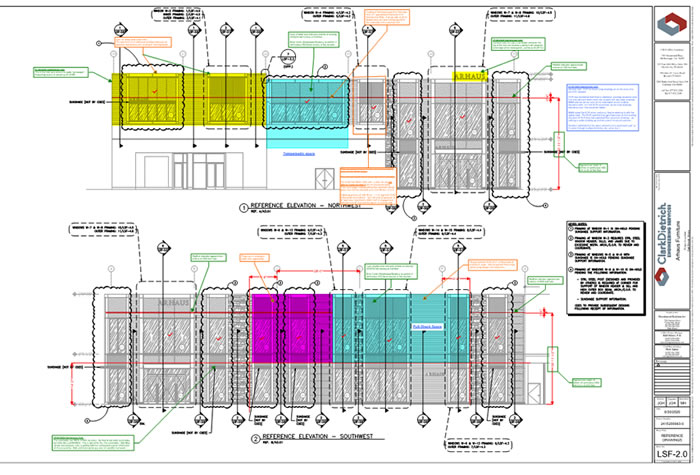

A renovation to an existing mall tenant space, this project included some unique exterior cold-formed wall framing conditions, including pilasters, “picture frame” style punched openings, and boxed headers supporting sunshades. Design Challenges and SolutionsAs with most renovation projects, the existing conditions are almost as important to know/understand as the intent of the new framing. With this space undergoing its second renovation in as many years, CDES needed to rely not only on the original existing building drawings, but also on the most current set of “existing” cold-formed steel shop drawings from the prior renovation which was completed in 2019. Typically, the drawings alone may not accurately depict the actual field conditions, especially if something was added/modified along the way via a sketch/addendum that may not have made its way into the final set of contract documents/shop drawings. So, CDES also needed to rely on strong communication with the contractors to understand all the existing conditions and come up with solutions that worked best for everyone involved.

Some of the adjacent tenants were undergoing renovations of their own at the same time, but of course they were at different stages of construction compared to our project. So, one of the challenges CDES had to face was to avoid any potential demolition of the adjacent tenant’s façades. In some locations, this meant that the new framing design had to be accomplished via a one-sided construction technique (from the inside only). Another challenge CDES had to resolve was with the pilaster framing, specifically with the in-plane wind load to which the side-faces of the pilasters would be subjected. Depending on the condition, the ACM clad pilasters protruded off the face of the building anywhere from 1 foot-2 inches up to almost 2 feet. By utilizing a series of continuous tracks and straps, CDES provided a load path from the pilaster back into the primary structure without needing any additional structural support. Luckily, the sunshades at the boxed beam locations proved to be a relatively straightforward task. The sunshades were more like “picture frames” in that the entire middle portion of the sunshades were wide open to the sky above, so the sunshade loads were minimal and primarily localized at the jamb locations.

With physical distancing required throughout the duration of this project because of the Covid-19 pandemic, site visits were held to a minimum. This forced the need for multiple photos, phone calls, etc. to perform “virtual” site visits to understand all the existing conditions. Additionally, there were some other issues where wider studs were needed to properly resolve all the design loads and still be within the design limits (e.g., deflection criteria). Fortunately, there was tremendous coordination and cooperation among the entire design and construction teams at all levels to communicate and work together to complete this project while incurring minimal added structural steel expense and preventing a delayed store opening for the owner. The Arhaus Furniture project is another fine example of technology coupled with great teamwork resulting in timely, cost-effective and contractor-friendly solutions.

|