2021 CFSEI CREATIVE DETAIL AWARD WINNERHONORABLE MENTIONSTRUCTURAL EVOLUTION – AVITA COMMUNITY PARTNERS BEHAVIORAL HEALTH FACILITY, HALL COUNTY, GEORGIA

Avita Community Partners Behavioral Health Facility Owner: Avita Community Partners Project BackgroundThe recently completed Avita Community Partners Behavioral Health Facility in Hall County Georgia was framed using long-span cold-formed steel rafters on load-bearing cold- formed steel parapet walls. Lateral stability was provided using light framed shear walls. Loads for the shear walls were provided by the engineer of record. Winter Construction was the contractor for the project. Structural Evolution, the cold-formed steel specialty engineer, was responsible for designing all framing and details for the building. One significant design challenge was that space allowed for shear walls was limited. Most walls had numerous window openings. Structural Evolution used ‘Woven X-Brace Shear Walls’ to support large lateral loads within short sections of wall. Design Challenges and Solutions

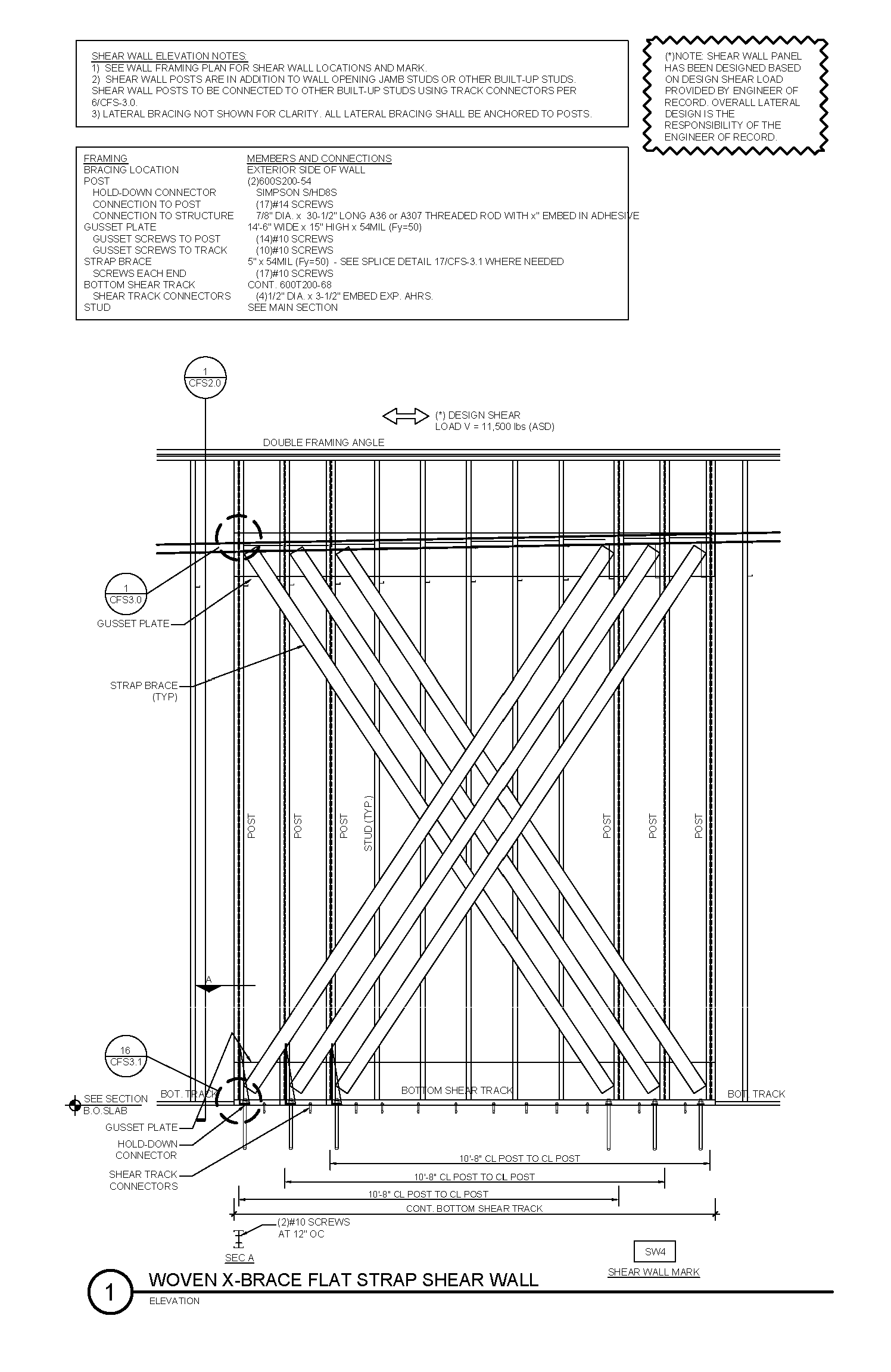

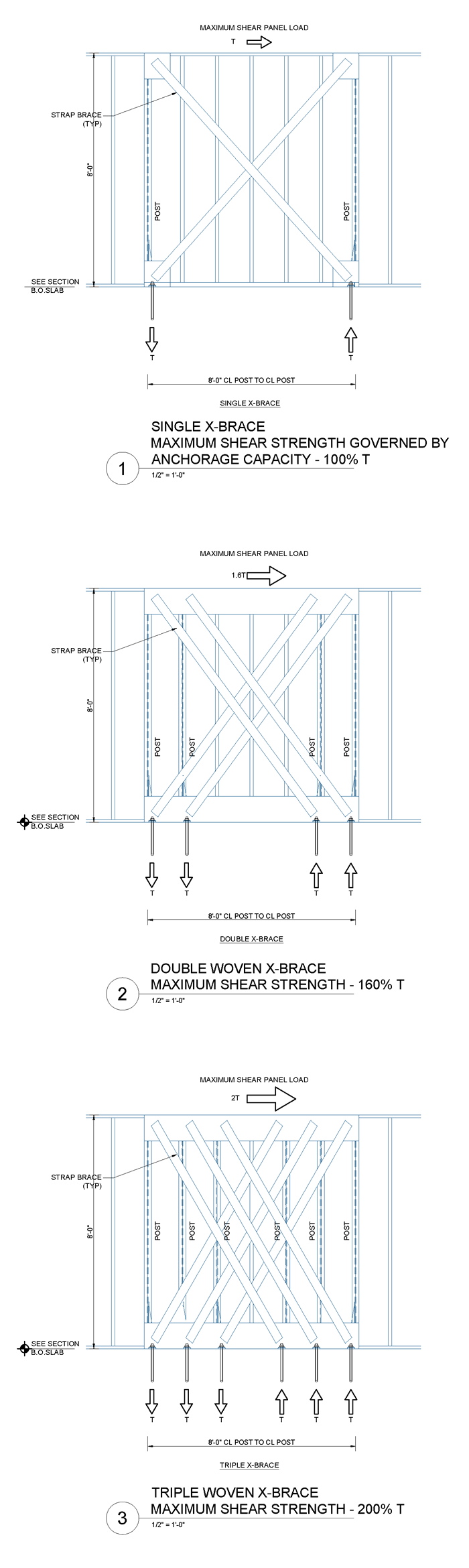

The mechanics of the woven X-brace shear wall are shown on the Drawing CFS-1. For a square shear panel, the lateral load (T) on the shear wall results in overturning forces of the same magnitude at the compression and tension posts as shown on Detail 1/CFS-1. To design a woven X-brace shear wall, the engineer must first determine the tension capacity of the post anchorage (T). Next, the engineer determines the number of woven X-braces needed to not exceed this tension capacity for each of the multiple post anchorages. Double or triple woven X-braces may be used as shown on Details 2 and 3/CFS-1. These overlapping woven braces will substantially increase the overall shear panel capacity. In the example shown on Sheet CFS-1, a double woven X- brace is 160 percent stronger than a single X-brace. A triple woven X-brace is 200 percent stronger than a single X-brace. The design of the woven X-brace elements is the same as the design of a typical X- bracing. Double and triple woven X-braces are 16” and 32” narrower that a single X- brace. This results in a narrower individual panel. A single wide gusset plate is used to evenly distribute loads to the individual woven X-braces. Drawing CFS-2 (and Detail 1) show the triple woven X-brace used on the Avita Community Partners Behavioral Health Facility. Strap bracing was placed on the exterior side of the wall only because this was a parapet wall. Strap and gusset plate thickness were limited to 54 mil to minimize material thickness build-up on the wall. Photos 1 and 2 show the installed woven X-brace. By allowing two or three X-braces to be in the same space, the Woven X-Brace Shear Wall is a terrific solution for providing high shear capacity within a limited length of wall. Courtesy of Structural Evolution

|