2021 CFSEI CREATIVE DETAIL AWARD WINNER

THIRD PLACE

THE LEFFLER GROUP – MONARCH CASINO RESORT SPA

BLACK HAWK, COLORADO

Monarch Casino Resort Spa Monarch Casino Resort Spa

488 Main Street,

Black Hawk, Colorado 80422

Owner: Monarch Casino and Resort, Inc.

Architect of Record: Joseph Marandola, AIA, LEED AP BD+C, MBA Architecture and Interior Design

Cold-Formed Steel Specialty Engineer: Daniel Stadig, P.E., The Leffler Group

Award Entry Submitted by: Daniel Stadig, P.E., The Leffler Group

Project Background

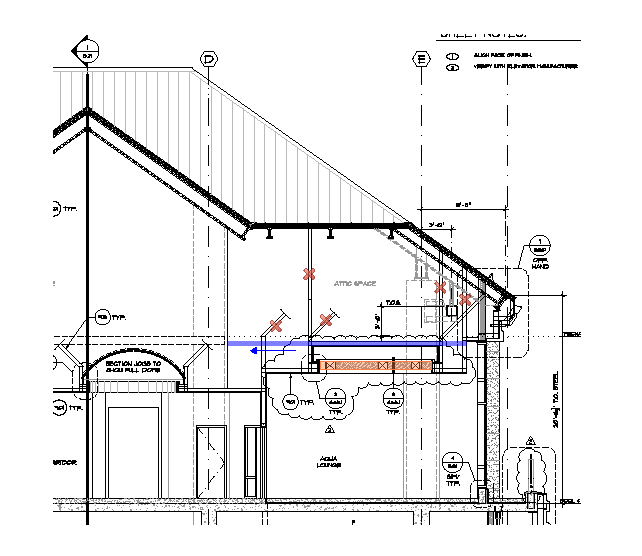

Level 23 Aqua Lounge Ceiling: This 23-floor casino and hotel expansion is in Black Hawk, Colorado, where typical mountain architecture involves high-sloped roofs to combat heavy snow seasons.

The top floor utilizes high ceilings and views with spa, pool decks, and other amenities. The 9:12 sloped roof height from finished floor ranges from about 24 feet at the eave to greater than 35 feet near the peaks.

Our client requested an engineered wall and ceiling solution for several areas on this floor to help save material and construction costs associated with spanning or hanging architectural framing from the high roof.

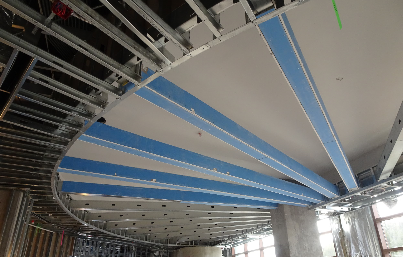

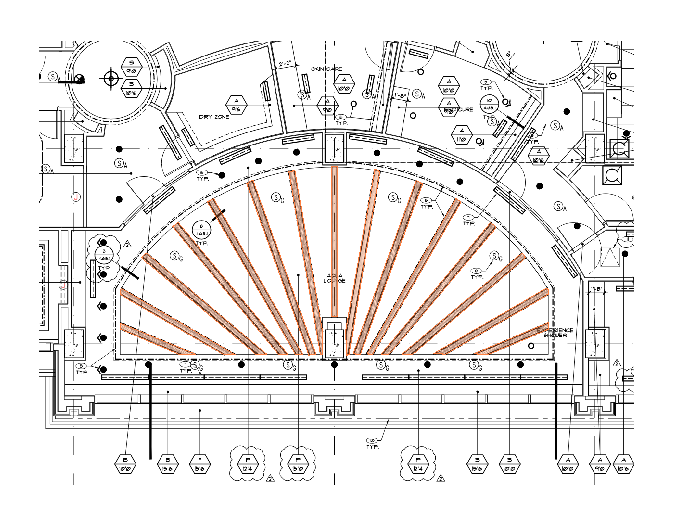

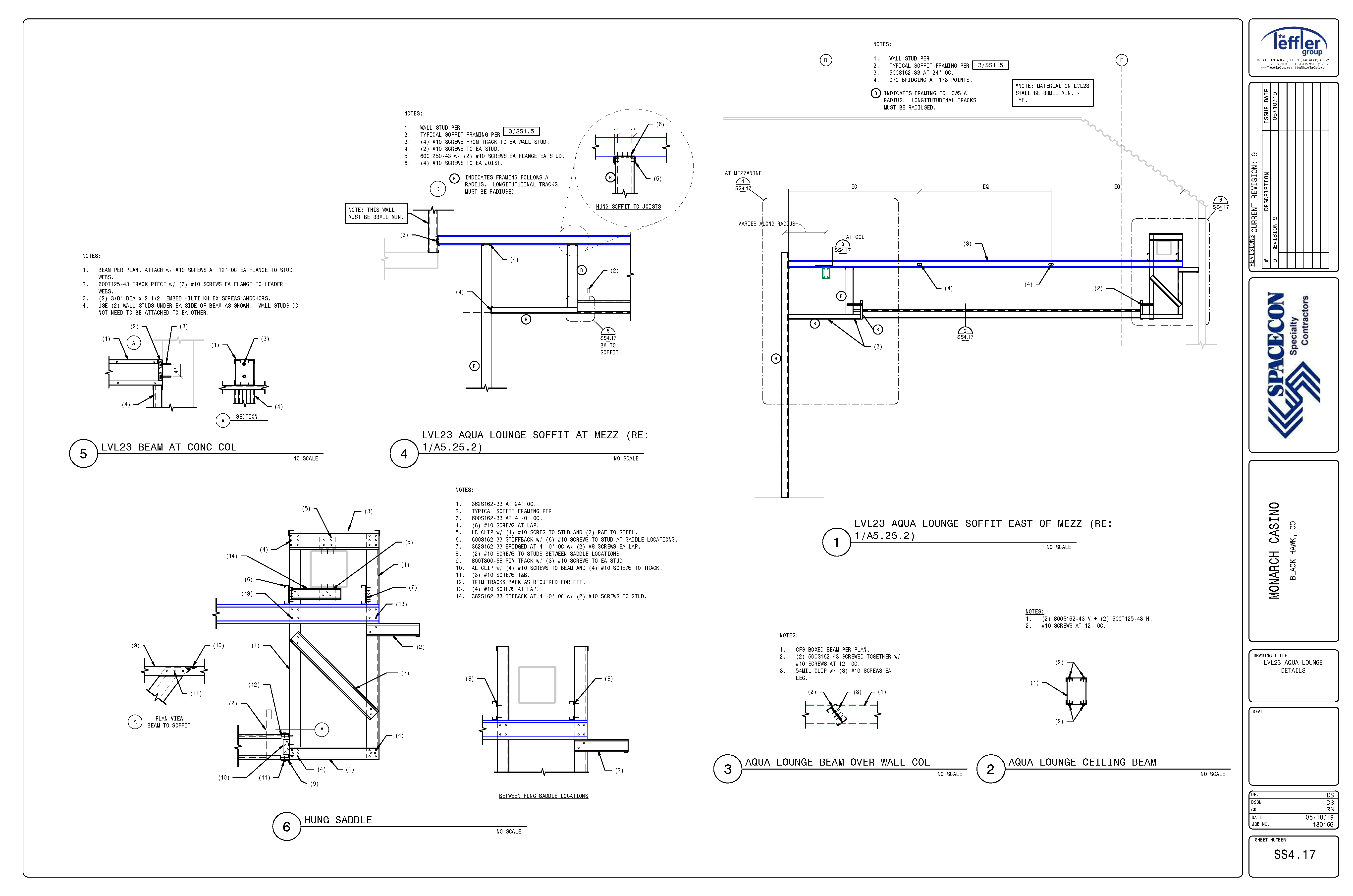

The aqua lounge ceiling is particularly intricate. The space is curved in plan, with a recessed ceiling emphasizing radial faux beams framed with cold-formed steel (CFS). The faux beams terminate into an associated radiused soffit along the perimeter of the room.

Our task was to create a framing solution that spanned the ceiling framing across this 25 ft. room without extending any CFS to the sloped roof above.

Framing detail techniques focused on the use of typical CFS material, specifying only mechanical or anchored fasteners and maintaining a reasonable load path to ensure proper installation.

Design Challenges and Solutions

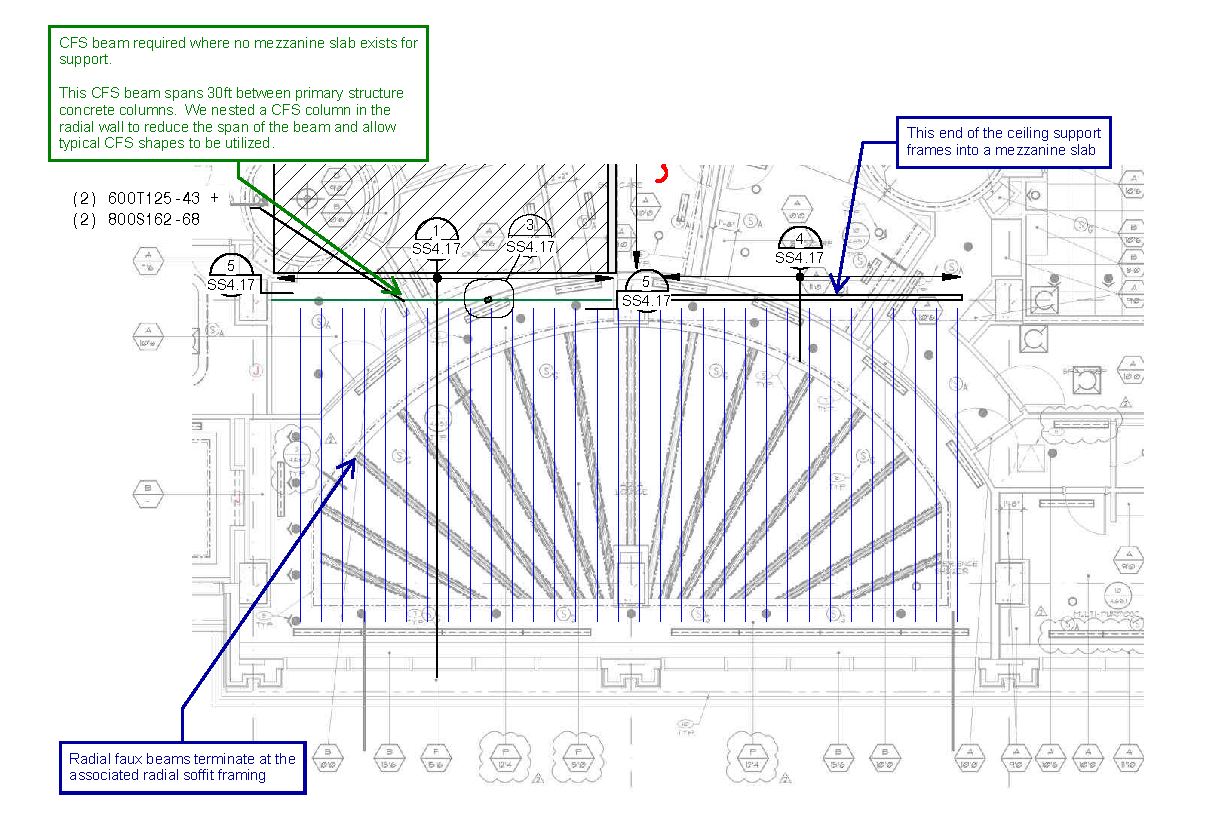

Ceiling Framing Details: The upper ceiling structure was designed to span the room and support all lower ceiling soffits and faux beams. This allowed the framer to employ standard curved framing techniques below where possible.

The available perimeter support for the upper joist framing varied:

- Tube steel girt framing above the ceiling was utilized along the exterior windows to create a saddle support for the upper ceiling joists.

- The curved perimeter required extension to a mezzanine slab for half of the ceiling.

- The other half required a CFS box beam to be installed spanning 30 ft. between primary structure concrete columns. We designed a nested CFS column within the room's curved perimeter wall to lower the CFS beam's span and allow lighter framing to be used.

The curved soffits and radiused faux beam layout were designed to hang from the CFS joists above.

CFS engineers are increasingly required for intricate interior framing design. It is important to understand the code differences and requirements for non-structural framing vs structural framing to best serve our clients and projects. This solution exemplifies efficient design and sensible load path achievement for an intricate ceiling framing system.

|