2020 CFSEI DESIGN EXCELLENCE AWARD WINNERFIRST PLACE – RESIDENTIAL/HOSPITALITYraSmith – HUB STATE STREET – WEST LAFAYETTE, INDIANA

Completed: August 2019 Owner: Core Spaces, UP Campus Properties. Project Background

The modern mixed-use building is an eclectic mix of studio, 1-, 2-, 3- and 4-bedroom units with choices of standard amenities or one of three special upgraded room packages. Approximately 600 beds are available, consisting of 226 fully furnished units occupying eight floors. Amenities include a fitness/weight room, yoga room, game room, sauna and grilling area. It also has West Lafayette’s first rooftop pool, in addition to a hot tub and sundeck. The three-story podium consists of retail space and restaurants at street level with parking and duplex units above. The Hub State Street structure comprises eight floors of post and beam with hollow core plank floors on top of three stories of concrete columns with post-tensioned slab at the podium. The exterior walls are primarily bypassing, non-load bearing prefabricated cold-formed panel frames supporting prefinished, prefabricated Stolite panels. raSmith provided shop drawings as well as panelized drawings and details to Grayhawk, LLC, which produced the panels in its shop. Design Challenges and SolutionsWhat makes Hub State Street unique is the exterior that was designed utilizing prefinished prefabricated panels with all cold-formed framing and connection elements located dimensionally on the building. Panelizing the exterior greatly reduced the amount of time needed for building envelope installation. It took only 68 days to erect the exterior panels. raSmith created the exterior shop drawings along with embed plans, panel layout plans, frame and finish panel tickets, and finish details.

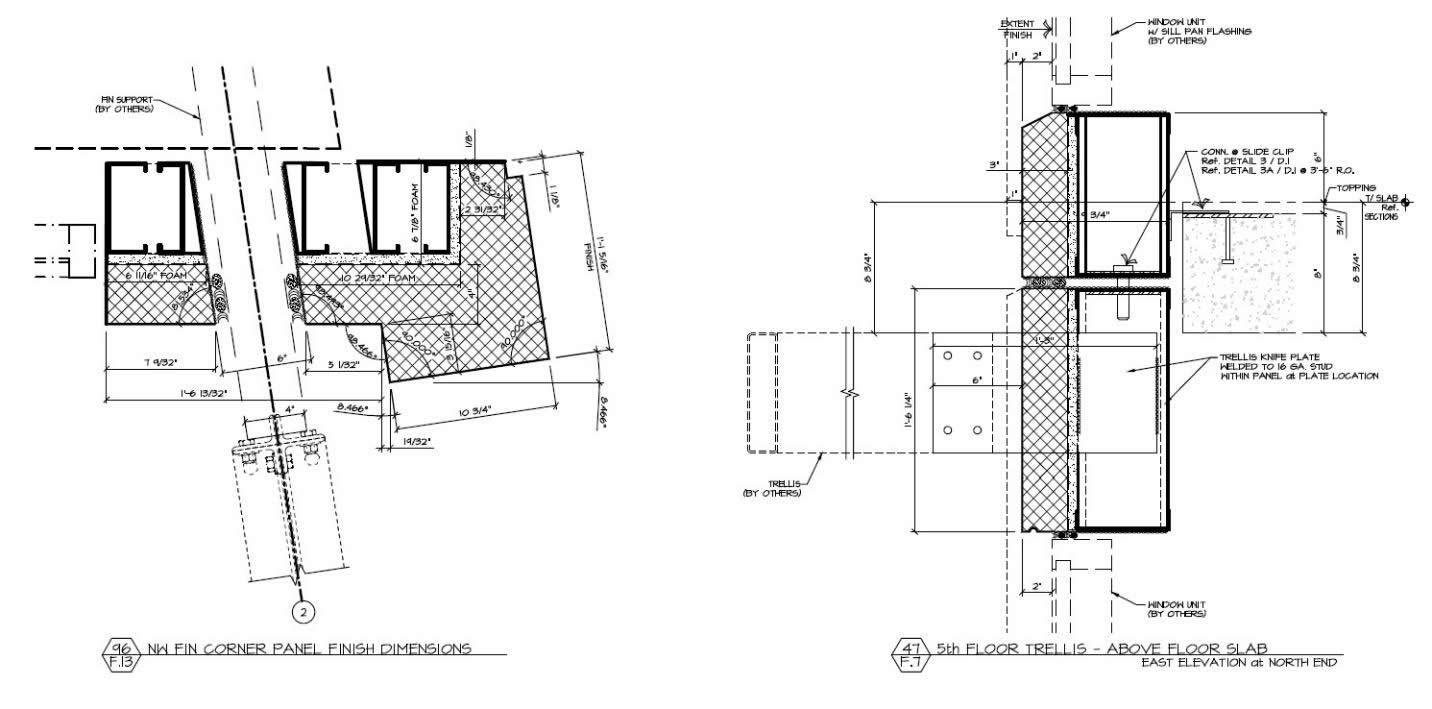

The exterior Stolite finish was designed in harmony with the framing, both by raSmith. Hub State Street included six different combinations of colored and textured foam, each with its own set of challenges. Six finishes were applied to varying panel templates based on the architectural design. These patterns included two brick patterns and colors, horizontal and vertical sawtooth with two colors, and flat dark gray and light gray colors. Thickness of the foam panels varied in depth. One reason was to accommodate the different horizontal reveals per the architect’s design. Each panel required two panel tickets for the shop: one for the frame, the other for the finish.

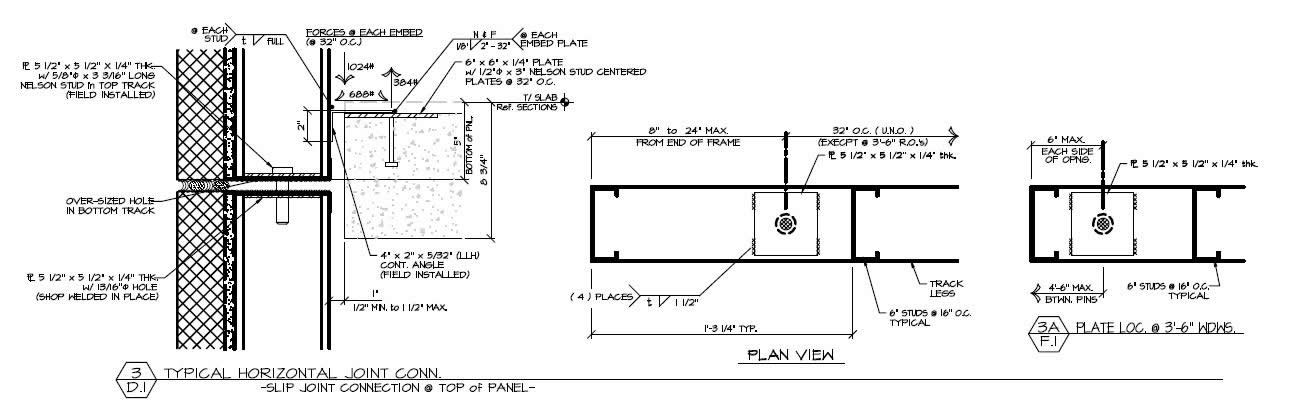

The Hub State Street has over 600 panels, with 400 different prefabricated panels and 200 different prefabricated Stolite finish panels. All panels are precisely dimensioned and fabricated to fit, similar to a puzzle. Most panels were designed as two stories tall and anywhere from 10 to 15 feet wide, stacked on each other via multiple slip pins, which precisely lock the panels in place. They also allow for lateral force in either direction. Due to a variety of protruding architectural and practical design elements, or conflicts with the primary structure, most panels are unique. Each elevation of the building is distinctively different with reveals, color finishes, patterns and design elements. These variations often necessitated different solutions affecting both foam and frame detailing.

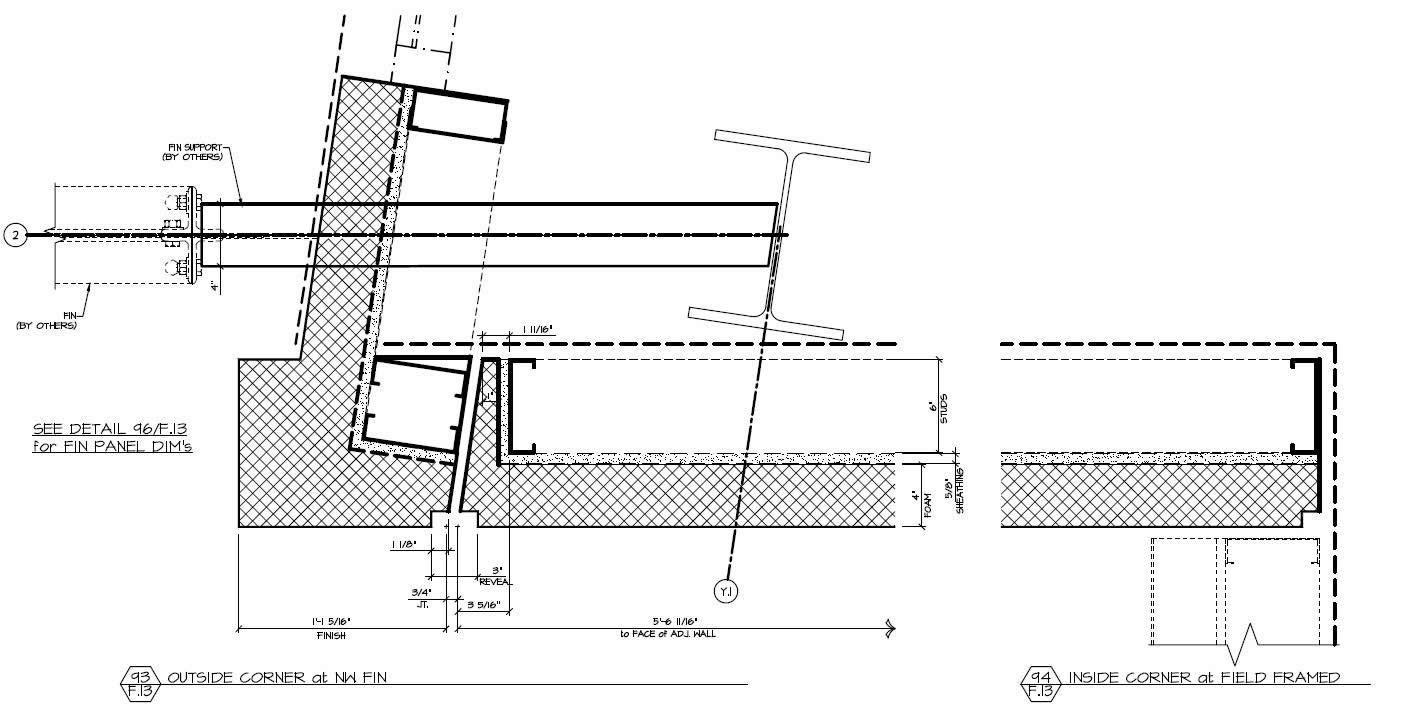

A fin sign with horizontal steel support in a skewed wall was another design element that required a creative solution. The steel support for the fin signage was preinstalled before panels were put onto the building. This required consideration of how the panels would be installed around the horizontal steel elements into the design of the panel, both affecting the cold-formed and the exterior finish.

|