2015 CFSEI DESIGN EXCELLENCE

AWARD WINNERS

FIRST PLACE

CLARKDIETRICH – AQ RITTENHOUSE

PHILADELPHIA, PA

AQ Rittenhouse

2021 Chestnut Street

Philadelphia, PA 19103

Completed: December 2014

Construction Cost: $33 million

Owner: Aquinas Realty Partners

Architect of Record: Stampfl Associates

Engineer of Record for Structural Work: Jannis Vacca, P.E.,

The Harman Group

Cold-Formed Steel Specialty Engineer: Wesley Burghardt,

ClarkDietrich Engineering (Lead Engineer)

Cold-Formed Steel Specialty Contractor: Anthony Faranda,

Clemens Construction Company, Inc.

Project Summary:

2021 Chestnut Street was originally a four-story structure located in downtown Philadelphia that served as an annex to the Mid-City YWCA. Falling into disrepair, the structure was closed and remained abandoned for 23 years. Aquinas Realty Partners purchased the property in 2012 with the vision of razing the existing building and creating a new, 12-story, luxury apartment complex. This structure would be composed of a structural steel frame, concrete slabs and exterior cold-formed steel framing. Today, that vision has been realized and 2021 Chestnut Street, now known as AQ Rittenhouse, stands as one of Philadelphia’s best residential complexes for upscale, urban living.

What made this project unique from a design and construction standpoint were a number of items, including an unorthodox approach to the exterior connection design, panelization of the wall framing, and Building Information Modeling (BIM). The smooth coordination between these processes allowed for many issues to be resolved prior to construction as well as an expedited construction timeline.

What made this project unique from a design and construction standpoint were a number of items, including an unorthodox approach to the exterior connection design, panelization of the wall framing, and Building Information Modeling (BIM). The smooth coordination between these processes allowed for many issues to be resolved prior to construction as well as an expedited construction timeline.

The cold-formed steel framing contractor, Clemens Construction, specifically faced several challenges in regards to the installation of the exterior, cold-formed steel stud framing. Not only were they faced with the usual issue of a short construction schedule, but they also faced the challenge of installing the framing in very tight quarters and within a high-traffic area. ClarkDietrich was chosen by Clemens Construction to help address these issues through the development of exterior framing details, engineering shop drawings, panelization drawings and BIM modeling.

In order to combat many of the job challenges at once, it was determined that the exterior framing would be panelized off-site. These panels would not only consist of the stud, track and connection framing, but also with the exterior sheathing and finishes applied. It was the design intent that these panels be constructed in a controlled environment, shipped to the job site and fastened in place with no additional, exterior finishing required. It was also determined by the design team that stud infill framing would not be a good solution, as the slab edge would be exposed after the panels were installed. This would cost additional time and money to field frame and finish the strips around the structure where the slab edge was exposed.

In order to combat many of the job challenges at once, it was determined that the exterior framing would be panelized off-site. These panels would not only consist of the stud, track and connection framing, but also with the exterior sheathing and finishes applied. It was the design intent that these panels be constructed in a controlled environment, shipped to the job site and fastened in place with no additional, exterior finishing required. It was also determined by the design team that stud infill framing would not be a good solution, as the slab edge would be exposed after the panels were installed. This would cost additional time and money to field frame and finish the strips around the structure where the slab edge was exposed.

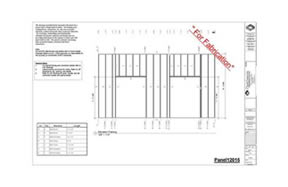

In conjunction with Clemens Construction, the engineering team at ClarkDietrich developed details in which double 118-mil (50ksi) bent angles were installed at each slab level. The top of the panels would then be field welded to the underside of these angles in order to support the lateral loads and the weight of the panels. The base of the panels would connect to these same angles, but also allow for vertical deflection between each level. This deflection at the base of the panels created another design issue. One of the custom bent angles would need to be manufactured with vertical slots at each stud and jamb. How would these slots be located and specified in order for the manufacturer to produce? The answer was BIM.

The engineering technicians at ClarkDietrich modeled every stud and track on the exterior of the building. From this BIM model, panel drawings were created, which gave the exact location of every typical stud, jamb, header, etc. on the project. Clemens Construction then took these panel drawings and determined the length of angles that would be needed, as well as the location of the vertical slots. This information was then transferred back to the ClarkDietrich production team, which manufactured each custom piece. The BIM model and panel drawings also allowed for the creation of a material list of the typical track and stud products. This list included the size and length of every framing piece in every panel. Again, supplying this information back to the ClarkDietrich production team made the process of ordering and producing the material smooth and efficient.

The engineering technicians at ClarkDietrich modeled every stud and track on the exterior of the building. From this BIM model, panel drawings were created, which gave the exact location of every typical stud, jamb, header, etc. on the project. Clemens Construction then took these panel drawings and determined the length of angles that would be needed, as well as the location of the vertical slots. This information was then transferred back to the ClarkDietrich production team, which manufactured each custom piece. The BIM model and panel drawings also allowed for the creation of a material list of the typical track and stud products. This list included the size and length of every framing piece in every panel. Again, supplying this information back to the ClarkDietrich production team made the process of ordering and producing the material smooth and efficient.

It was a combination of outside-the-box thinking on the engineering side and a well-constructed BIM model on the technical side that made 2021 Chestnut Street a unique and ultimately successful project for all parties involved. The finished structure turned what was once a vacant and uninhabitable eyesore into a 12-story, 110-unit luxury apartment complex that is now the jewel of the block.

Download Case Study