2025 CFSEI DESIGN EXCELLENCE AWARD WINNER

SECOND PLACE - COMMERCIAL

McCLURE – PROJECT BLUE - FONTAINEBLEAU LAS VEGAS LOBBY

LAS VEGAS, NEVADA

Project Blue - Fontainebleau Las Vegas Lobby Project Blue - Fontainebleau Las Vegas Lobby

2777 Las Vegas Boulevard

Las Vegas, Nevada 89109

Completion Date: 2024

Owner: Fontainebleau Development.

Architect of Record: Bergman Walls and Associates.

Engineer of Record for Structural Work: John A. Martin & Associates.

Cold-Formed Steel Specialty Engineer: Josh Garton, P.E., S.E., McClure.

Cold-Formed Steel Specialty Contractor: Jeff Montague, Radius Track.

Award Entry Submitted by: Lauren Gutknecht, McClure.

Project Background

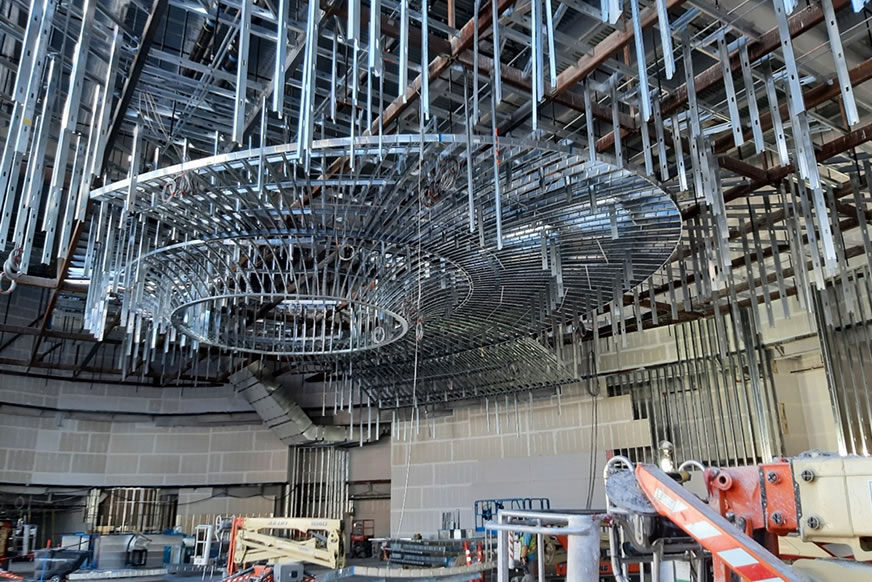

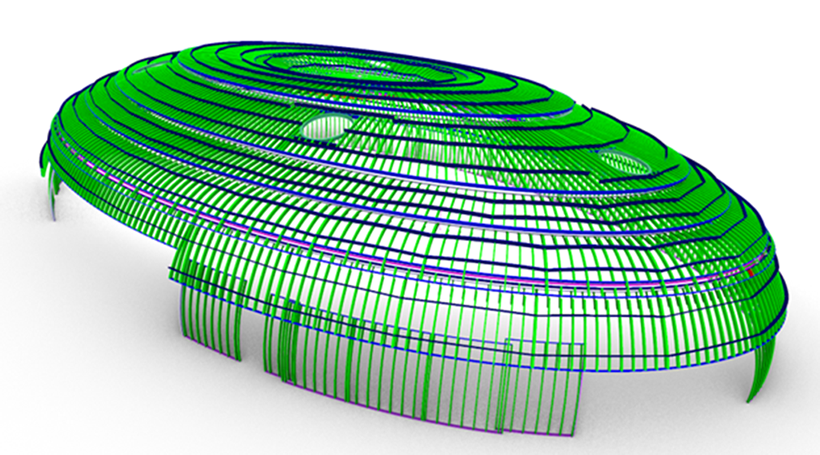

The interior cold-formed steel (CFS) ceiling and wall panels for a newly constructed casino features a structural steel framework of beams and bar joists. The design centers on a series of doubly curved, prefabricated CFS ceiling panels that form interlocking “clouds” throughout the Fontainebleau lobby. Each ceiling panel was assembled offsite. They were installed on-site with only a few connections. Prefabrication enabled the design team achieved continuous fluidity in the ceiling’s shapes, reducing field labor and ensuring precise geometry.

Design Challenges and Solutions

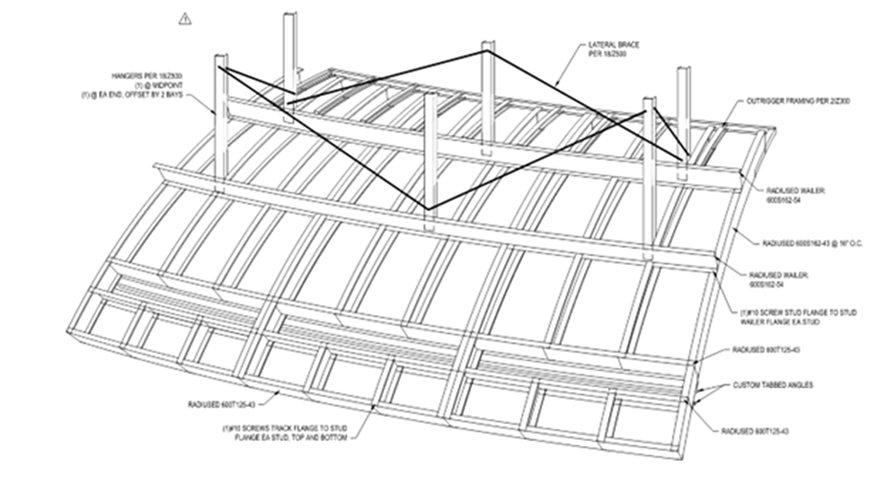

Curved Ceiling Assembly: The Fontainebleau lobby ceiling was designed as an overlapping series of “leaf” panels, each containing primarily raised ribs spaced at 16 inches on center.

The ribs are engineered from custom crimped radiused studs based on testing and detailed calculations of the behavior of crimped members. These ribs are supported by a pair of radiused wailers that are hung from the overhead structural system. The panels’ perimeter framing tapers to widths as narrow as 1⅝ inches, accommodating overlaps between panels while maintaining a sleek profile.

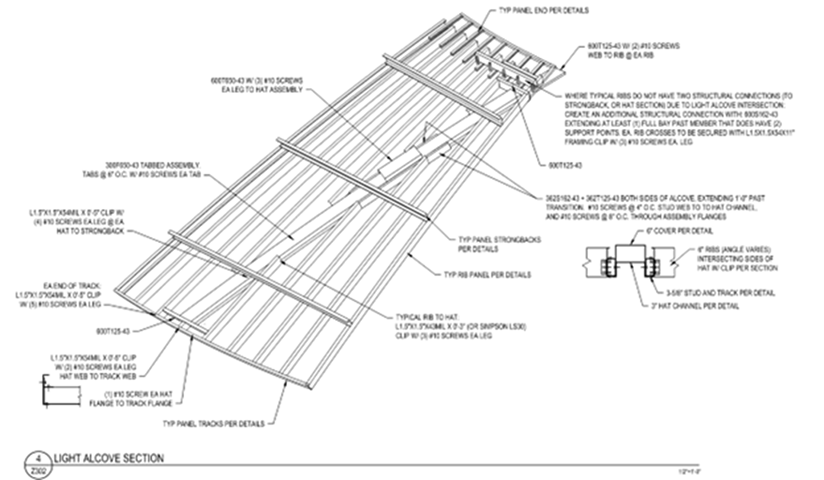

Additional challenges arose around incorporating diffusers into the lower edges of the panels. To integrate air distribution seamlessly, the design required doubly curved openings with specialized headers and jambs.

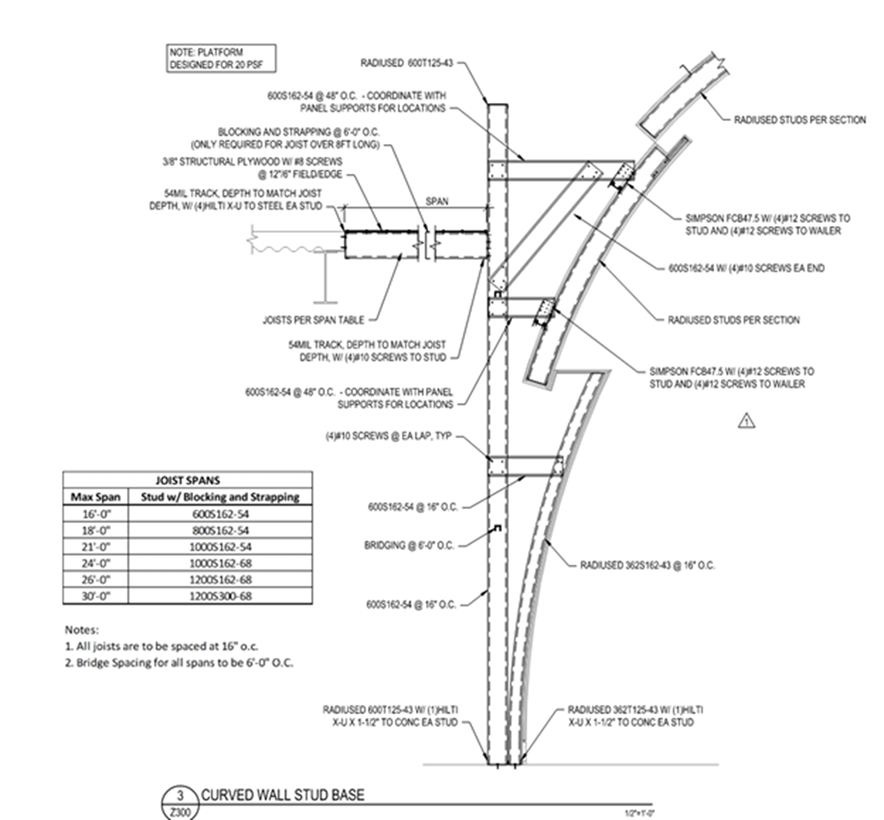

Seismic Considerations: The project’s seismic design category placed requirements on the design of the interior ceiling system. Diagonal bracing was necessary within each panel to provide independent stability. Lower-tier ceiling levels were supported by either ground-based framing or trussing against adjacent walls, which limited the number of overhead hangers.

A movement joint was discreetly integrated within the ceiling’s lighting alcoves, which ensured they remained visually minimal. These low walls often did not have adequate structure behind them for attachment, requiring joists up to 30ft long to reach back to adjacent structures for lateral support.

Design Adaptations: After fabrication and shipment, the building’s ownership elected to add recessed lighting alcoves that cut across multiple ceiling panels. This late-stage change required a detailed notching plan so that the newly introduced light alcoves could be partially inserted into the assembled stud framing on site. The retrofit was prefabricated and sent to the jobsite, where it was cut into the project while retaining the structural capacity of the panels.

Conclusion

Project Blue Lobby demonstrates how CFS can be used to create visually striking, highly customized interior elements. From the doubly curved prefabricated ceiling clouds to the hidden movement joints and last-minute design changes, this project highlights the adaptability of CFS systems in complex, high-seismic environments. The resulting lobby not only meets demanding structural criteria, but also delivers a dynamic and modern interior aesthetic for Las Vegas’s newest casino attraction.

|